Introduction to WPC Compounding Machines

Wood-plastic composite (WPC) compounding machines are at the forefront of innovative manufacturing, providing a pathway for producing a blend of wood fibers and thermoplastics. These machines are pivotal in creating materials that combine the aesthetics of wood with the durability of plastics, widely used in decking, fencing, and automotive interiors.

Types and Applications

The applications of WPC compounding machines are diverse, catering to various industries that require durable and sustainable materials. These machines are essential in producing WPC for outdoor decking, which demands weather resistance and long-lasting performance. In the automotive sector, WPC components are valued for their strength-to-weight ratio and are used in interior panels and trims.

Features and Performance

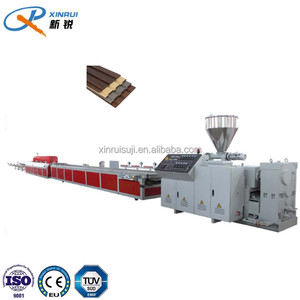

A WPC extrusion machine is characterized by its robust construction and advanced control systems, ensuring consistent output. The twin-screw extruder is a popular choice for its efficiency, blending materials thoroughly to produce a homogeneous mixture. Single-screw extruders, while simpler in design, are suitable for less complex compounding tasks and are appreciated for their ease of operation.

Material Handling and Efficiency

Efficiency in material handling is crucial, and WPC pelletizing machines excel in this aspect. They are designed to handle a variety of raw materials, including recycled plastics, which supports sustainable manufacturing practices. The precision in temperature control and feeding systems in a WPC granulation machine ensures that the material properties are maintained throughout the process.

Advantages of WPC Compounding

The advantages of using a WPC making machine are manifold. These machines offer the flexibility to produce a range of WPC products with different proportions of wood to plastic, allowing for customization in density and rigidity. The end products are not only environmentally friendly but also resistant to decay, providing a long-lasting alternative to traditional materials.

Choosing the Right Machine

Selecting the appropriate WPC compounding machine involves considering the specific requirements of the production process. Factors such as the desired output rate, the type of raw materials used, and the intended application of the final product are critical in determining the most suitable machine configuration.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4