Popular in your industry

Related Searches:

Top categories

About welding products philippines

The welding machine Philippines is a versatile tool that joins two or more metal pieces by melting them together. It is an essential equipment in various industries, including construction, manufacturing, and automotive. It is available in different types, each catering to specific welding needs. One of the common types of welding machines is the stick welding machine, also known as an arc welding machine. It uses an electrode, a welding rod coated with a flux material, and an electric current to create an arc between the electrode and the workpiece, generating the heat needed to melt the metals and form a strong bond.

Features of welding machine Philippines

Another type of welding machine is the MIG welding machine, which stands for Metal Inert Gas. It uses a wire electrode and a shielding gas, typically a combination of argon and carbon dioxide, to protect the weld pool from atmospheric contamination. The wire electrode is continuously fed through the welding gun, allowing for a semi-automatic welding process. MIG welding machines are commonly used in industries that require high productivity and the ability to weld a variety of metals. A TIG welding machine, or Tungsten Inert Gas, is a precise and clean welding process that uses a non-consumable tungsten electrode to create the arc. It is often used for welding thin materials and in applications where aesthetic welds are required. TIG welding offers better control over the welding parameters, such as heat input and arc length, making it suitable for welding aluminum, stainless steel, and exotic metals.

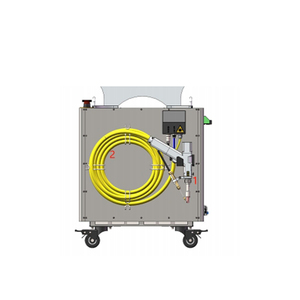

A plasma cutter, though not a welding machine, is often used in conjunction with welding for cutting metal. A plasma cutter uses a high-velocity jet of ionized gas, or plasma, to cut through electrically conductive materials. It is a versatile cutting tool that can produce clean and precise cuts, making it an essential equipment in metal fabrication and welding shops.

Advantages of welding machine Philippines

Apart from the range of welding machines available, it is essential to consider the project requirements, the type of material to be welded, and the desired welding process before selecting a welding machine. For example, a stick welding machine is a reliable and versatile option for field welding and can be used on a variety of metal thicknesses. A MIG welding machine is ideal for welding projects that require high productivity, such as in automotive and manufacturing industries. A TIG welding machine is suitable for welding thin materials and for making precise and aesthetically pleasing welds. The choice of a plasma cutter is based on the material thickness and the desired cutting speed. Considering these factors will help in selecting the most appropriate welding machine for the job.

It is important to consider the safety features and cooling system of the welding machine to ensure the operator's safety and prevent overheating during prolonged use. A portable welding machine is a compact and lightweight welding tool that provides flexibility and ease of use for welding projects in various locations. It is often used in construction, repair, and maintenance work where the welding machine needs to be transported to different job sites. The welding machine price ph varies based on the type, brand, and features of the machine. The cost of a welding machine is influenced by factors such as its power source, welding capacity, and additional features. A basic stick welding machine is more affordable, while advanced models with multiple welding processes and digital controls are more expensive. The cost of a welding machine is an important consideration, and factors such as the type of welding process, material thickness, and project requirements should be weighed to determine the most cost-effective option.

Factors to consider while choosing a welding machine in Philippines

When choosing a welding machine, it is important to consider factors such as the type of welding process, material thickness, power source, and additional features. The welding process should be selected based on the project requirements and the materials to be welded. For example, stick welding is suitable for welding thicker materials, while MIG and TIG welding are ideal for thin and precise welding. The welding machine's power source should be compatible with the available power supply, and factors such as portability and ease of use should be considered. Additional features, such as digital controls, adjustable settings, and safety features, can enhance the welding machine's performance and user experience.

It is important to follow the manufacturer's guidelines and safety precautions while using the welding machine. Regular maintenance, such as cleaning and inspection, should be carried out to ensure the machine's optimal performance and longevity. The portable welding machine price Philippines is influenced by various factors, such as the brand, type, and features of the machine. It is essential to compare prices from different suppliers and consider the overall value and quality of the welding machine before making a purchase.