Popular in your industry

Top categories

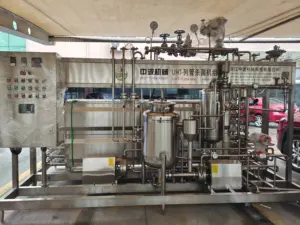

About uht for juice

UHT (Ultra-High Temperature) for juice is a pasteurization method that treats liquid food, particularly fruit juice, at a very high temperature for a short period to achieve commercial sterility, extending its shelf life significantly. This process is vital in the production of long-lasting, safe-to-consume fruit juices, eliminating harmful bacteria and microorganisms in the beverage. The UHT process is a paramount step in the manufacturing of UHT fruit juices, UHT juice, like apple and orange juices, ensuring their quality, safety, and extended shelf life.

Types of UHT for Juice

There are two primary types of UHT for juice: direct and indirect heating. Direct heating involves passing the juice through a steam injection system, quickly raising its temperature to the desired level, usually around 135-150°C. On the other hand, indirect heating utilizes a heat exchanger, where the juice is heated indirectly by steam or hot water. This method allows for more precise control over the heating process and is commonly used for heat-sensitive juices or those prone to fouling. Both types of UHT systems have their advantages and are chosen based on the specific requirements of the juice being processed.

Advantages of UHT for Juice

The UHT process has several advantages that make it a preferred method for juice pasteurization. One of the primary benefits is its ability to achieve commercial sterility, eliminating harmful microorganisms and ensuring the safety of the juice. This process also helps in preserving the nutritional value and sensory attributes of the juice, such as taste and color, as it involves minimal heat exposure compared to traditional pasteurization methods. Additionally, UHT-treated juices can be stored at room temperature, eliminating the need for refrigeration until opened, which is convenient for both manufacturers and consumers. The extended shelf life of UHT juices reduces food waste and allows for wider distribution, making it a cost-effective solution in the juice industry. Moreover, the UHT process offers flexibility in processing various types of juices, including those with natural or added sugars, as it can be customized to suit different product requirements.

Applications of UHT for Juice

The UHT process is widely used in the production of various types of fruit juices, including apple, orange, and mixed fruit juices. UHT for juice is particularly suitable for fruit juices that are prone to microbial contamination or those that require an extended shelf life without the need for preservatives. UHT apple juice and UHT orange juice are popular examples of UHT-treated beverages, known for their convenience and long-lasting freshness. These juices are commonly found in retail settings, such as supermarkets and convenience stores, offering consumers a convenient and safe way to enjoy their favorite beverages. The UHT process is also utilized in producing juice concentrates, which can be reconstituted with water to create ready-to-drink juices, catering to the diverse preferences of consumers. In the food service industry, UHT juices are used in various applications, including in restaurants, hotels, and catering services, where the convenience of long shelf life and easy storage is highly valued. This process is also used in producing juice-based beverages, such as fruit drinks, nectars, and blends, offering a wide range of choices to consumers. The UHT process is an essential technology that revolutionizes the juice industry, ensuring the availability of safe, nutritious, and flavorful fruit juices for consumers worldwide.