Introduction to Thinner Production Lines

The thinner production line is an industrial assembly of machinery and equipment designed for the formulation and packaging of thinning agents used in paint, coatings, and other industrial processes. This category encompasses a variety of machines that work in unison to ensure the efficient production of thinners, which are essential for modifying the viscosity of paints and coatings for application purposes.

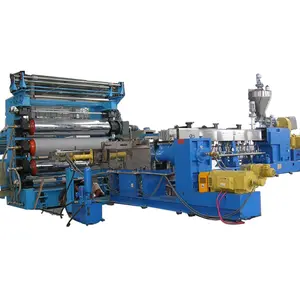

Components and Functionality

A typical thinner production line includes equipment such as mixers, reactors, storage tanks, filling machines, and labeling systems. Each component plays a pivotal role in the production process, from the initial mixing of raw materials to the final packaging of the product. The machinery is engineered to handle volatile organic compounds safely and with precision, ensuring consistent product quality and adherence to industry standards.

Types and Applications

There are various types of thinner production lines tailored to different scales of operation and end-use applications. Some lines are designed for the production of general-purpose thinners, while others are specialized for automotive, industrial, or eco-friendly water-based thinners. The application of these thinners spans across numerous industries, including automotive refinishing, furniture manufacturing, and industrial coatings, highlighting the versatility of the production lines.

Features and Materials

Modern thinner production lines are equipped with advanced features such as automated control systems, high-precision filling, and robust safety mechanisms. The construction materials for the machinery are selected based on chemical compatibility and durability, often including stainless steel and other corrosion-resistant alloys to withstand the harsh chemical environment and ensure a long service life.

Advantages of Streamlined Production

Investing in a streamlined thinner production line offers numerous advantages, such as enhanced production efficiency, reduced labor costs, and minimized waste. Automation in these lines ensures precise formulation and consistency, which is crucial for maintaining the efficacy of thinners. Additionally, the integration of modern technology facilitates real-time monitoring and troubleshooting, further optimizing the production process.

Environmental Considerations

Environmental considerations are increasingly important in the design and operation of thinner production lines. Manufacturers are adopting greener technologies and practices to reduce emissions and waste. This includes the implementation of solvent recovery systems and the use of environmentally friendly raw materials, aligning with global sustainability efforts.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4