Popular in your industry

Related Searches:

Top categories

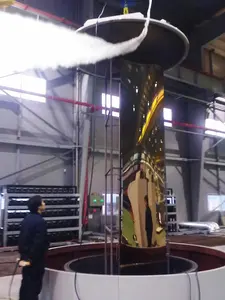

About steel pipe coating machine

Introduction to Steel Pipe Coating Machines

Steel pipe coating machines are integral components in the protection and enhancement of pipe durability. These machines apply a protective layer that shields the pipes from corrosion, weather, and mechanical damage. The application of coatings extends the life of steel pipes, making them a crucial step in the manufacturing and maintenance of pipelines.

Types and Applications

There are various types of steel pipe coating machines catering to different applications. From smaller units designed for precise work to larger, industrial-scale machines, the variety ensures that there is a solution for every scale of operation. These machines are utilized in numerous sectors, including construction, oil and gas, and water transportation, to provide a protective barrier for steel pipes against harsh environmental conditions.

Operational Features

The operational features of a steel pipe coating machine include advanced control systems, often equipped with PLCs (Programmable Logic Controllers) for precision and consistency in coating. The machinery is designed to handle various coating materials, from epoxy to polyurethane, ensuring a versatile application range. The efficiency of these machines is reflected in their ability to coat pipes of different sizes and lengths with uniformity and speed.

Materials and Advantages

The materials used in the coating process range from thermoplastic to fusion bonded epoxy, each providing unique benefits. The advantages of using a steel pipe coating machine include improved pipe longevity, resistance to corrosive substances, and enhanced physical protection. By applying a consistent and even coating, these machines play a pivotal role in infrastructure development and maintenance.

Choosing the Right Machine

Selecting the right steel pipe coating machine involves considering the specific requirements of the task, such as the type of coating material, the size of the steel pipes, and the desired throughput. It is essential to choose a machine that aligns with the operational capacity of the manufacturing plant or construction site to ensure optimal performance and output.

Maintenance and Sustainability

Maintenance of a steel pipe coating machine is critical for its longevity and performance. Regular upkeep ensures that the machine operates at peak efficiency and continues to produce high-quality coatings. Additionally, modern machines are designed with sustainability in mind, aiming to reduce waste and energy consumption during the coating process.