Introduction to Sisal Machines

Sisal machines are integral components in the agricultural and textile industries, designed for processing sisal, a natural fiber derived from the Agave sisalana plant. These machines are engineered to extract, process, and prepare sisal for various applications, ranging from rope making to textiles. The efficiency of sisal processing machines has revolutionized the sisal industry, enhancing productivity and reducing the need for intensive manual labor.

Types of Sisal Processing Equipment

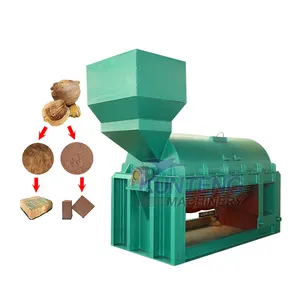

The sisal industry utilizes a variety of machines, each serving a specific function in the processing chain. The sisal decorticator is a prominent example, designed to strip the husk from sisal leaves and extract the fibers. For further refinement, sisal fiber extraction machines are employed to separate the fibers from residual plant matter. Additionally, sisal rope making machines are specialized equipment tailored to twist and wind sisal fibers into sturdy ropes.

Applications and Features

Sisal machines are versatile, catering to a broad spectrum of applications. They are crucial in food processing industries for shelling nuts and grains, while in the textile sector, they are used to produce sisal yarns and ropes. These machines boast features such as robust construction, efficiency in fiber extraction, and adaptability to various sisal grades. The adaptability ensures that they meet the diverse needs of different processing lines.

Materials and Advantages

Constructed from durable materials, sisal machines withstand the rigors of processing operations. The use of high-grade metals ensures longevity and resistance to wear. The advantages of using these machines are manifold, including significant time savings, consistent fiber quality, and the ability to handle large volumes, which manual processing cannot match.

Choosing the Right Sisal Machine

Selecting the appropriate sisal decorticator machine depends on several factors, including the scale of operations and the specific type of sisal product being manufactured. Prospective buyers should consider the machine's capacity, efficiency, and compatibility with their existing production lines. While the sisal decorticator machine price is a consideration, the focus should be on the machine's features and the value it adds to the processing line.

Conclusion

In conclusion, the integration of sisal machines into the processing of natural fibers is indispensable for modern industries. These machines enhance efficiency, ensure quality, and support large-scale operations. Alibaba.com serves as a gateway for businesses to explore a diverse range of sisal processing equipment, connecting them with manufacturers to find the right machinery to meet their operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4