Popular in your industry

Related Searches:

Top categories

About shoe making production line

Introduction to Shoe Making Production Lines

The shoe making production line is an assembly of specialized equipment designed to facilitate the various stages of shoe manufacturing. This line streamlines the process from raw material to finished product, ensuring efficiency and consistency in production. The integration of advanced machinery and technology has revolutionized the footwear industry, allowing for the mass production of shoes while maintaining quality and design standards.

Types of Machinery in Shoe Production

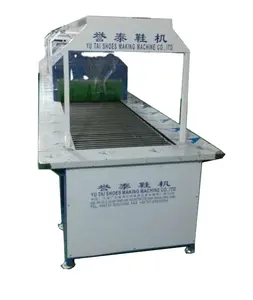

Within a shoe making production line, several types of machinery are employed. Cutting presses and clicker cutter machines are utilized for precise material shaping, while embroidery machines add intricate details or branding elements to the shoes. Advanced machinery, such as steamers, softens materials for better molding, and pressers aid in the assembly process. The line may also include specialized equipment for applying footwear primer, cement, and for pressing outsoles onto the shoes.

Applications and Features

The application of a shoe making production line extends across various types of footwear, from casual shoes to formal wear, and even specialized athletic shoes. Each machine within the line is designed to perform specific tasks with precision, contributing to the overall functionality and aesthetic of the shoe. Features of these machines often include automation for increased production speed, programmability for diverse shoe designs, and adaptability to different materials and sizes.

Materials and Advantages

A shoe making production line handles a wide array of materials, including leather, textiles, synthetics, and rubber. The advantage of using such a line lies in its ability to maintain material integrity while efficiently producing footwear. The mechanized process reduces manual labor, minimizes errors, and increases output, which is crucial for meeting market demands.

Choosing the Right Shoe Making Equipment

Selecting the appropriate machinery for a shoe making production line requires consideration of the workshop size and the desired production capacity. It is essential to ensure that the equipment fits within the workspace without hindering the workflow. Prospective buyers should assess the specifications of each machine to match their production needs, taking into account factors such as output rate, compatibility with other equipment, and the types of shoes intended for production.

Optimizing Your Production Line

Optimizing a shoe making production line involves not just the right selection of machinery but also understanding the workflow and production goals. Alibaba.com, as a leading B2B platform, connects buyers with a diverse range of machinery suppliers, offering various options to suit different production scales and requirements. Utilizing the platform's filter functions can aid in narrowing down the choices, ensuring a well-suited and efficient production line setup.