Popular in your industry

Related Searches:

Top categories

About pu injection pump

Introduction to PU Injection Pumps

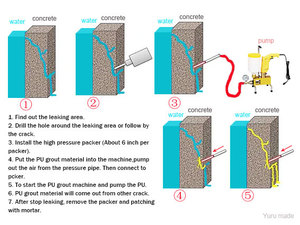

Polyurethane (PU) injection pumps are specialized devices designed for the precise application of polyurethane foam in various construction and repair scenarios. These pumps are integral to processes that require the injection of PU foam for insulation, stabilization, and waterproofing tasks.

Types and Applications

The versatility of PU injection pumps is reflected in their various types, such as the polyurethane injection pump and the polyurethane grout injection pump. Each type serves specific applications ranging from concrete slab lifting to soil stabilization and waterproofing in complex construction projects.

Features and Efficiency

A PU grouting machine is engineered for efficiency and precision. These machines boast features that allow for adjustable pressure settings, ensuring the accurate delivery of PU foam. The efficiency of a PU injection grouting machine lies in its ability to expedite construction tasks while enhancing safety and reducing labor intensity.

Materials and Durability

Constructed from robust materials, PU grouting pumps are designed for durability and longevity. The components of these pumps are often made from high-strength metals and alloys, capable of withstanding the rigors of construction environments while ensuring consistent performance.

Advantages of Using PU Injection Pumps

The use of a PU injection pump in construction projects offers numerous advantages. These pumps facilitate a cleaner application process, minimize waste, and provide a level of control that manual applications cannot match. Furthermore, the precise application reduces the risk of material overuse, translating to cost-effectiveness in the long run.

Choosing the Right PU Injection Pump

Selecting the appropriate polyurethane grout pump involves considering the specific requirements of the project. Factors such as pump capacity, injection pressure, and the type of polyurethane foam used are critical in determining the most suitable pump for a given task.