Popular in your industry

Related Searches:

Top categories

About polyester yarn spinning machine

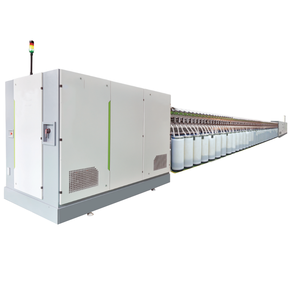

Polyester Yarn Spinning Machine: An Overview

The textile industry's backbone is arguably the polyester yarn spinning machine, a pivotal component in the production of synthetic fibers. This machinery is engineered to convert polyester into yarns that are then woven into fabrics. The versatility of these machines allows for a wide range of yarn types, including the increasingly popular fdy yarn machine variant, which is specifically designed for producing Fully Drawn Yarn used in high-strength applications.

Types and Applications

There are primarily two types of polyester spinning machines: the single screw and the double screw. The double screw polyester yarn spinning machine is renowned for its efficiency, effectively increasing output due to its dual-screw system. Conversely, the single screw variant is more suited to smaller-scale operations. These machines are integral in creating a multitude of products, from durable pipes and sheets to delicate plastic films and bowls, showcasing their wide application range.

Features and Materials

A polyester spinning machine is not just about spinning; it's about precision and durability. Many components, such as weft feeders and electronic weft selectors, are crafted from ceramics, ensuring longevity and ease of maintenance. The robust nature of these machines means they can handle various inputs, from virgin polyester pellets to recycled powders, making them a cornerstone in both primary production and recycling operations.

Advantages of Modern Spinning Machines

The modern polyester yarn making machine brings forth a plethora of advantages. Standardization and accuracy are at the forefront, with advanced machines offering unparalleled flexibility in production. The adaptability of these machines to various production scales makes them a valuable asset for manufacturers looking to optimize their operations without compromising on the quality of the yarn produced.

Maintenance and Durability

Maintenance is a critical aspect of ensuring the longevity of a polyester yarn spinning machine. The ceramic components not only provide strength but also facilitate easy cleaning, which is essential to prevent clogging and maintain efficiency. Regular upkeep helps in sustaining the performance of the machine over extended periods, making it a reliable choice for continuous production environments.

Conclusion

In conclusion, whether for large-scale production or smaller, specialized batches, the right polyester yarn spinning machine can significantly impact the efficiency and quality of output. While Alibaba.com serves as a platform connecting buyers with a diverse range of suppliers offering these machines, it is crucial to consider the specific needs of your operation when selecting the appropriate machinery. With a comprehensive understanding of the types, applications, and benefits, businesses can make informed decisions to meet their textile production requirements.