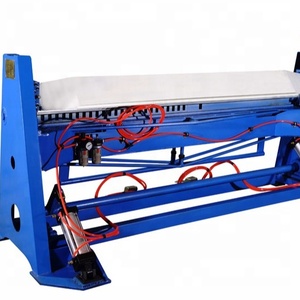

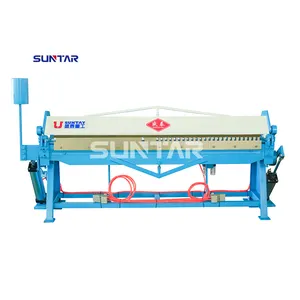

Pneumatic Bending Machines: An Overview

The realm of metal fabrication is incomplete without the mention of pneumatic bending machines. These machines are pivotal in shaping and curving metal sheets with precision and efficiency. A pneumatic bending machine utilizes compressed air to exert force on metal, ensuring consistent bending without the need for manual effort.

Types and Applications

From pneumatic tube benders to pneumatic sheet bending machines, the variety caters to different industry needs. The pneumatic pipe bending machine is ideal for creating precise angles on pipes, while the pneumatic rod bending machine is tailored for solid rods. Each type serves a unique function, whether in construction, automotive, or manufacturing industries.

Features and Materials

These machines are designed to handle various metals, from aluminum to stainless steel. The construction of a pneumatic bar bending machine includes high-grade materials that ensure durability and longevity. Features such as adjustable bending angles and customizable dies make these machines versatile for different bending tasks.

Advantages of Pneumatic Benders

The advantages of using a pneumatic bender are manifold. They offer efficiency in repetitive tasks, reduce labor costs, and provide uniform results. The pneumatic tmt rod bending machine exemplifies this by delivering precise bends on thermo-mechanically treated rods, which are commonly used in construction.

Considerations for Purchase

When selecting a electro pneumatic tube bending machine, factors such as tonnage, bending length, and size are crucial. Tonnage, or bending force, is essential for determining the machine's capability to shape metal without distortion. The bending length dictates the maximum length of metal that can be bent, and the size of the machine should be compatible with the available workspace.

Conclusion

In conclusion, a pneumatic bending machine is a vital asset for metal fabrication. With a range of machines available, it is important to choose one that aligns with your specific requirements. While exploring options, consider the machine's features, the type of metal it can handle, and its overall efficiency to ensure it meets your fabrication needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4