Popular in your industry

Related Searches:

Top categories

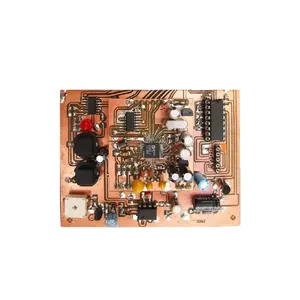

About paper phenolic pcb

A paper phenolic PCB is a type of printed circuit board that utilizes a paper phenolic resin as the composite material for its base. This material is known for its insulating properties and is commonly used in a variety of electrical applications. The paper phenolic PCB is favored for its cost-effectiveness and durability, making it a suitable choice for a wide range of electronic devices.

Types and Characteristics of Paper Phenolic PCBs

Different types of paper phenolic PCBs are designed to cater to various applications. For instance, the FR1 paper base phenolic copper clad laminate sheet is specifically tailored for single-layer PCBs, where the focus is on rigidity and durability. On the other hand, PCBs utilizing Phenolic Laminate Bakelite Sheets are sought after for their high mechanical strength and low moisture absorption, making them ideal for environments where humidity is a concern. Each type presents unique characteristics such as thermal and electrical insulation properties, which are critical in high voltage and high temperature applications.

Structure and Operation of Paper Phenolic PCBs

The structure of a paper phenolic PCB is meticulously designed to ensure optimal performance. The base material, typically consisting of layers of paper impregnated with phenolic resin, is complemented by copper cladding for conductivity. The intricate network of copper tracks is etched onto the board, forming the circuit which directs the flow of electricity. This precise structure allows for the seamless operation of the PCB, with each component—from the raw water tank to the collector in the case of a distilling water machine—playing a vital role in the overall functionality of the electronic device.

Materials and Properties

The materials used in paper phenolic PCBs are chosen for their specific properties that benefit electronic applications. Paper provides a cost-effective and stable base, while phenolic resin offers excellent electrical insulation and resistance to heat. When enhanced with materials like PP, carbon fiber, or wood pulp, the PCB can withstand higher voltages, operate at increased temperatures, or provide better dimensional stability, respectively. These material choices are crucial for ensuring that the PCB can reliably meet the technical demands of its intended application.

Business Usages and Applications

Paper phenolic PCBs are integral in various business sectors. In the automotive industry, they are used in control systems due to their durability and heat resistance. Consumer electronics manufacturers rely on them for everything from kitchen appliances to personal gadgets, valuing their cost-effectiveness and reliable performance. In high-voltage applications, such as power supply units, the PCBs' insulating properties are crucial. These diverse applications illustrate the value that paper phenolic PCBs bring to businesses by enhancing product reliability and efficiency.

Functions and Tasks

The primary function of a paper phenolic PCB is to provide a stable and conductive platform for mounting electronic components. It facilitates the electrical connections necessary for the device to perform its specific tasks, whether that's processing data in a computing device or regulating temperature in a heating system. The PCB's design ensures that it can handle the electrical load and distribute power evenly, contributing to the overall functionality of the electronic device.

Features and Unique Selling Points

The distinct features of paper phenolic PCBs include their excellent dielectric strength and mechanical toughness. These PCBs are also known for their ease of machining and good wear resistance, which make them suitable for a variety of electronic products. Compared to other types of PCBs, paper phenolic boards are more affordable, which is a significant selling point for cost-sensitive applications without compromising on quality and performance.

Benefits and Positive Outcomes

The benefits of using paper phenolic PCBs are manifold. They provide a reliable foundation for electronic circuits, ensuring long-term functionality of devices. Their thermal stability and electrical insulation properties protect against circuit failures, which can be critical in safety-sensitive applications. By using these PCBs, manufacturers can achieve a balance between cost efficiency and dependable performance, ultimately leading to customer satisfaction and loyalty.

How to Use and Maintain Paper Phenolic PCBs

Effective operation of paper phenolic PCBs involves proper installation and maintenance. Ensuring that the PCB is correctly seated and that all connections are secure is vital for optimal performance. Regular inspections can identify potential issues before they lead to failures. For maintenance, keeping the PCB clean and free from contaminants is essential. Dust and debris can be gently removed with approved cleaning solutions and soft cloths to prevent damage to the board and its components.

Choosing the Right Paper Phenolic PCB

Selecting the appropriate paper phenolic PCB requires an understanding of the device's electrical requirements and the operating environment. Factors such as voltage rating, thermal resistance, and physical size must be considered. It's also important to evaluate the manufacturer's reputation and the quality of their materials to ensure that the PCB will perform as expected over its intended lifespan.

Installation Guidelines

Installation of a paper phenolic PCB should be carried out with precision. The board must be aligned correctly within the device, and all electronic components should be securely attached. It's crucial to follow the manufacturer's guidelines to avoid any damage to the board or the device it will power.

What are the key features to look for in a paper phenolic PCB?

When evaluating a paper phenolic PCB, key features to consider include the quality of the phenolic resin, the thickness and uniformity of the copper cladding, the precision of the circuit pattern, and the board's overall dimensional stability and tolerance to environmental factors.

How does the choice of material affect the performance of a paper phenolic PCB?

The choice of material in a paper phenolic PCB directly impacts its performance. High-quality paper and phenolic resin ensure better insulation and durability, while the inclusion of materials like carbon fiber can enhance the board's strength and resistance to high temperatures.

What should businesses consider when integrating paper phenolic PCBs into their products?

Businesses should consider the electrical requirements of their products, the operating environment, and the expected lifespan when integrating paper phenolic PCBs. It is also important to partner with a reputable supplier who can provide PCBs that meet industry standards and are consistent in quality.