Popular in your industry

Related Searches:

Top categories

About pallet nailing table

What is Nailing Table For Pallet Assembly

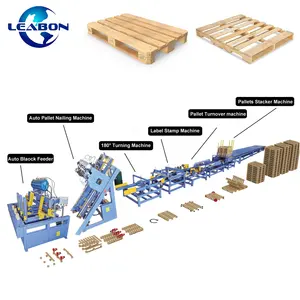

Nailing tables for pallet assembly are specialized workbenches designed to facilitate the nailing or stapling of boards, typically made from wood or other pallet materials. These tables provide a stable and flat surface that supports the pallet during construction, ensuring precision and efficiency in the nailing process. They are an essential tool for carpenters, manufacturers, and construction professionals who require a dedicated workspace to assemble pallets quickly and securely.

The design of nailing tables often includes features such as adjustable heights, ergonomic work areas, and sturdy construction to handle the force required for fastening. They can be equipped with clamps or jigs that hold the boards in place, making it easier to work on them. The principle of their operation is straightforward: by stabilizing the pallet and holding the components at the correct angles, these tables help workers nail boards together in a uniform manner, which is crucial for the structural integrity of the pallet.

Nailing tables come in various configurations and can be tailored to suit specific production needs. Some are simple and stationary, while others are complex and mobile, with wheels that allow them to be easily relocated within a workspace. Their functionality extends beyond mere support; they are designed to enhance the speed, accuracy, and safety of pallet assembly compared to traditional methods.

Types of Nailing Tables for Pallet Assembly

The variety of nailing tables available caters to different types of applications and requirements in the industry. Here are some common variations:

-

Standard Nailing Table: This type is designed for general use and typically includes a level working surface with a sturdy frame. It's well-suited for most common pallet assembly tasks in workshops or small factories.

-

Rotating Nailing Table: A rotating table allows workers to assemble a pallet without moving around it. The table rotates so that each side can be nailed without needing to lift the material. This type is particularly useful for larger or heavier pallets.

-

Manual Nailing Table: Ideal for smaller operations or DIY enthusiasts, manual nailing tables provide a hands-on approach using a hammer. They're versatile and can be used for various types of pallet construction.

-

Hydraulic Nailing Table: These tables use hydraulic pressure to drive nails into the pallet material. They are powerful and designed for heavy-duty use, often found in industrial settings where large, solid pallets are common.

-

Automatic Nailing Table: For high-volume production, automatic nailing tables offer speed and consistency. They often come with features like nail counters and can handle multiple rows of nails in one pass.

How to choose Nailing Table For Pallet Assembly

Selecting the right nailing table for pallet assembly involves understanding the specific needs of your business's operations. Consider these factors when choosing a table:

-

Production Volume: The quantity of pallets you need to assemble will determine whether you need a manual or automated nailing table. For high-volume production runs, an automated table would likely be more efficient.

-

Pallet Size: The dimensions of your pallets will dictate the size of the table surface you require. Ensure that the table can accommodate your largest pallets or multiple smaller ones if necessary.

-

Nailing Pattern: The pattern in which nails are driven into the pallet should align with your needs. Some patterns offer more holding power while others might be more suited for temporary fastening.

-

Workspace Layout: The design of the table should complement your workspace flow. Consider how much room you have and how the table will integrate with existing machinery or assembly lines.

-

Flexibility: Depending on your product range, you may need a table that can adapt to different sizes and types of pallets or a specific configuration like block-style or stringer. Some tables offer customization options to tailor the workspace to your exact needs.

By carefully evaluating these considerations against your operational requirements and budget constraints, you can select a suitable nailing table that will enhance the efficiency and safety of your pallet assembly processes.

About Nailing Table For Pallet Assembly on Alibaba.com

Alibaba.com stands out as an international marketplace that connects businesses with a vast selection of suppliers offering nailing tables for various industrial applications. With an extensive range of products that cater to different business needs—from bulk manufacturing to specialized woodworking shops—Alibaba.com serves as a hub where customers can find high-quality nailing tables tailored to their operational requirements.

Whether you're seeking durable steel tables for heavy-duty construction work or portable aluminum options for on-the-go repairs, Alibaba.com simplifies the procurement process with user-friendly search capabilities that let you filter products by key specifications such as core components, machinery test reports, applications, local service locations, and even after-sales service options. This allows businesses to compare features and prices efficiently while ensuring they receive equipment that aligns with their business objectives.

Moreover, Alibaba.com's commitment to facilitating secure transactions is embodied in services like Trade Assurance which safeguards payments until delivery is confirmed. With its global reach across over 190 countries and areas, Alibaba.com empowers businesses to source their ideal nailing tables with confidence—knowing they're engaging with vetted suppliers on a platform designed with their procurement needs in mind.

Common FAQs for Nailing Table For Pallet Assembly

What is a nailing table used for in pallet assembly?

A nailing table is a workbench specifically designed for the assembly of pallets, allowing workers to easily build the pallets at a comfortable height and angle, reducing strain and improving efficiency in the assembly process.

How does a nailing table facilitate the assembly of pallets?

Nailing tables facilitate the assembly process by providing a flat, stable surface at an ergonomic height for workers, which allows them to work on the pallets without having to bend or stoop excessively.

Are there different types of nailing tables for different pallet sizes?

Yes, nailing tables come in various sizes to accommodate different pallet dimensions, from small to large. It's important to choose the right size for the specific assembly requirements.

Can nailing tables be customized according to specific requirements?

Many suppliers offer customization options for nailing tables, including specific dimensions, additional features, and custom color schemes to meet unique assembly needs.

What materials are nailing tables typically made from?

Nailing tables are often constructed from durable materials such as steel or iron to withstand the high force applied during nailing operations.

How do I determine the right height for a nailing table?

The height of a nailing table should be ergonomically suitable for the worker's height to prevent unnecessary bending or stooping and to maximize their productivity.

What after-sales services are available for nailing tables?

After-sales services for nailing tables can include online support, video technical support, and field maintenance and repair services. Availability may vary by supplier.

Are there portable nailing tables available?

Yes, some nailing tables are designed to be portable, with features like foldability and lightweight construction to facilitate easy movement between job sites.

How do I ensure that the nailing table is stable during use?

Stability during use can be ensured by choosing a table with a sturdy construction, adjustable legs, and a design that accommodates the weight and size of the pallets being assembled.

What key selling points should I consider when selecting a nailing table for my business?

Key selling points to consider include ease of operation, high productivity, long service life, competitive pricing, after-sales service options, and the ability to handle various types of pallets.

Is it possible to find environmentally friendly nailing table options?

While traditional metal nailing tables are not inherently eco-friendly due to their material composition, some suppliers may offer alternative materials that minimize environmental impact.

How do I choose between a manual and pneumatic nailing table?

The choice between manual and pneumatic (air-powered) nailing tables depends on the volume of nailing required and the accessibility to power sources. Pneumatic options are typically faster and more consistent for high-volume use.

Can I find nailing tables suitable for both small-scale operations and large industrial projects?

Yes, nailing tables are available in various sizes to cater to different levels of production—from small-scale home improvements to large industrial projects requiring high-volume nailing.

What is the difference between foldable and non-foldable nailing tables?

Foldable nailing tables are designed for easy storage and transport, while non-foldable models are typically used in permanent or high-volume settings where portability is not a primary concern.