Introduction to Mosaic Tile Molds

Mosaic tile molds are essential tools in the creation of intricate and decorative tiles used in various settings. These molds provide the framework for crafting durable and aesthetically pleasing tiles that can be used in both residential and commercial spaces. The versatility of mosaic tile mold designs allows for a wide range of applications, ensuring that each tile has a unique appeal.

Types and Applications

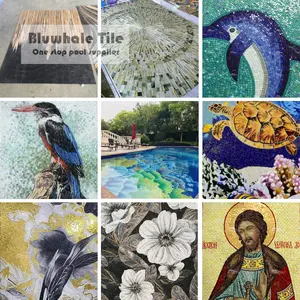

The types of molds available cater to different design requirements, from simple geometric shapes to complex patterns. Mosaic coaster mold options are popular for creating functional yet decorative pieces, while larger molds are suited for wall tiles and flooring. The application of these molds extends to public art installations, kitchen backsplashes, bathroom walls, and even outdoor pathways, showcasing their adaptability to various environments.

Features and Materials

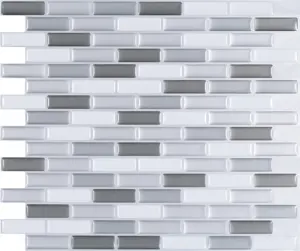

A mould for mosaic tile can be crafted from various materials, each offering distinct advantages. Iron molds are known for their durability and longevity, while silicone and plastic variants provide flexibility and ease of demolding. The choice of material often depends on the complexity of the design and the desired finish of the mosaic tile. Features such as standardized lift bars and connection sizes can be incorporated to streamline the production process.

Advantages of Using Mosaic Tile Molds

Utilizing molds for tile production offers several benefits, including consistency in tile size and shape, and the ability to reproduce designs accurately for large-scale projects. The efficiency of using a mosaic tile mold also reduces waste, as excess materials can be minimized. Moreover, the reusability of molds ensures that they are a cost-effective solution for ongoing tile manufacturing.

Choosing the Right Mold

Selecting the appropriate mold for a project involves considering the design intricacy and the type of material to be used. Suppliers on Alibaba.com provide a range of options, allowing for customization to meet specific production needs. It is essential to evaluate the compatibility of the mold with the intended tile material to ensure optimal results.

Streamlining Production with Molds

For businesses looking to enhance their production efficiency, opting for molds with standardized features can be beneficial. This standardization allows for the seamless interchangeability of parts and easier handling during the manufacturing process. By choosing the right mosaic tile mold, producers can achieve a balance between customization and mass production, catering to diverse market demands.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4