Magnesium Connecting Rods: An Overview

Magnesium connecting rods are integral components in various mechanical assemblies, offering a unique combination of lightness and strength. These rods serve as essential links within the kinetic chain of machinery, translating motion and forces in a precise and controlled manner. The use of magnesium alloy in their construction provides a distinct advantage in applications where weight reduction is crucial without compromising structural integrity.

Types and Applications

The diversity of magnesium connecting rods caters to a broad spectrum of industries. From automotive to aerospace, these rods are pivotal in applications demanding high performance and reduced weight. In the automotive sector, they are often employed in engine assemblies to enhance efficiency and performance. The aerospace industry values them for their ability to withstand high-stress conditions while minimizing the overall weight of the aircraft.

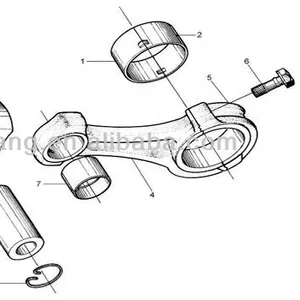

Features and Materials

Magnesium connecting rods are known for their exceptional features, including resistance to wear and high-temperature performance. The materials used in these rods are typically high-grade magnesium alloys, known for their excellent strength-to-weight ratio. These alloys are often combined with other metals to enhance properties such as ductility and corrosion resistance, making the rods suitable for challenging environments.

Advantages of Magnesium Connecting Rods

The advantages of using magnesium connecting rods are manifold. Their lightweight nature contributes significantly to the overall reduction of machinery mass, leading to improved efficiency and lower energy consumption. Additionally, magnesium's inherent damping capabilities help reduce vibrations, leading to smoother operation and extended lifespan of the components they integrate with.

Durability and Customization

Durability is a hallmark of these connecting rods, with many being anodized or powder-coated to enhance their longevity and resistance to environmental factors. Customization options are available, allowing for the rods to be tailored to specific requirements, ensuring compatibility and optimal performance in their designated applications.

Environmental Considerations

In an era where environmental considerations are paramount, magnesium connecting rods offer an eco-friendlier alternative to heavier metals. Their lighter weight contributes to reduced emissions in automotive applications, and their recyclability aligns with sustainable manufacturing practices.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4