Popular in your industry

Related Searches:

Top categories

About led light pcb with battery

What is Led Light Pcb Battery Integration

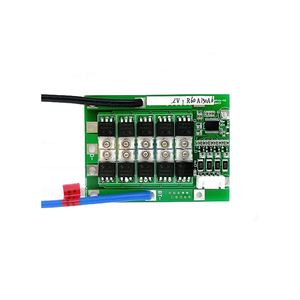

LED Light PCB (Printed Circuit Board) Battery Integration refers to the process of combining a PCB specifically designed for LED lighting with a battery to create a power supply unit for an LED light fixture. This integration is typically carried out by manufacturers or professionals in the lighting industry who require a reliable and compact power source for LED lights in various settings such as residential, commercial, or outdoor environments.

The LED light PCB battery integration process involves the assembly of the components onto the PCB, which may include LED modules, driver circuits, and other necessary parts. These components are then connected to a power source, often a battery, which is integrated into the light fixture. The power supply unit's main purpose is to regulate the voltage and current to the LEDs, ensuring they receive a consistent and efficient power supply.

LED light PCB battery integration is crucial for businesses that focus on creating portable lighting solutions like flashlights or camping gear. It allows these products to be rechargeable and thus more environmentally friendly and cost-effective for end-users. The integration process is governed by industry standards that ensure the safety and performance of the integrated components, making it an essential step in LED light manufacturing and assembly.

Types of LED Light PCB Battery Integration

The market offers a variety of LED light PCB battery integration types to accommodate different lighting needs and preferences. Each type is tailored for specific applications:

-

Standard LED Light PCB Integration: This is the most common type used for general lighting applications. The standard LED light PCB includes an array of LEDs wired in a simple circuit and is designed to be compatible with standard LED drivers. It is often used for home lighting, commercial lighting, and outdoor applications such as streetlights.

-

High-Power LED Light PCB Integration: High-power PCBs are used when more intense lighting is required, such as in industrial or stadium lighting. They can handle higher currents and typically support larger LED loads, making them suitable for high-output lighting systems.

-

LED Light PCB Integration with Integrated Battery Systems: These are designed for applications where a reliable backup power source is necessary, such as emergency lighting systems or outdoor solar-powered lamps. The integrated battery system ensures that the light will continue to function even during power outages.

-

Smart LED Light PCB Integration: Smart LED light PCBs are equipped with features like dimmability and color temperature adjustments. They can be controlled through apps on mobile devices and offer convenience and energy savings in environments like homes or offices.

-

LED Flexible Strip Light PCB Integration: These are used in applications that require lighting flexibility, such as accent lighting or backlighting. The PCBs can be bent around curves or corners and fit into tight spaces, making them ideal for complex lighting designs.

Each type of integration has its common use cases based on their characteristics such as power requirements, color options, and control capabilities. The integration type dictates how the final LED light application will be deployed and managed.

How to choose Led Light Pcb Battery Integration

Choosing the right LED Light PCB Battery Integration requires careful consideration of several factors. For businesses engaged in B2B sales focusing on bulk purchases for commercial use or resale, it’s essential to understand the diverse requirements of the intended application.

Firstly, consider the type of lighting needed for your application. For instance, if you're supplying products for emergency lighting systems, selecting PCBs that can handle sudden power surges and maintain illumination through battery integration would be critical. On the other hand, if your clients need components for display lighting or accent lighting within retail environments, you should provide options that offer control features for brightness and color temperature adjustments.

Secondly, evaluate the form factor and design requirements of the product. The PCB layout must be conducive to mounting batteries and suitable for integration within the product’s housing. It’s also important to consider any specific customization needs your clients might have regarding shapes, sizes, or circuit designs.

Additionally, assess the capacity and voltage specifications needed for your application. LED Light PCB Battery Integration products come in various capacities and voltage ratings designed to work with different configurations of LEDs while maintaining operational stability.

Lastly, take into account any additional features that might be necessary such as waterproofing for outdoor applications or built-in charging circuits for integrated solutions. By carefully evaluating these considerations against the types of PCB Battery Integration products available on Alibaba.com, businesses can make informed decisions that best suit their needs.

About Led Light Pcb Battery Integration on Alibaba.com

Alibaba.com stands out as an exceptional marketplace that brings together a vast array of suppliers offering LED light PCB battery integration solutions tailored for business needs. With an extensive network of manufacturers from around the globe, Alibaba.com facilitates the discovery of innovative products that meet diverse requirements without compromising on quality. Whether you're looking for standard solutions or customized options that cater to specific design specifications – Alibaba.com's platform simplifies sourcing by providing detailed product descriptions and supplier profiles.

Businesses can engage with suppliers directly through Alibaba.com's user-friendly interface, which supports communication in multiple languages and offers integrated order handling services that streamline the procurement process. Additionally, Alibaba.com's Trade Assurance service provides peace of mind by safeguarding payments until order fulfillment is confirmed.

The platform's commitment to helping small and medium-sized businesses scale up is evident through its provision of online trade solutions that empower companies at every stage of their growth journey. By choosing Alibaba.com for sourcing LED light PCB battery integrations, businesses leverage not only a comprehensive product selection but also a trusted environment where quality meets reliability in international trade solutions.

Common FAQs for Led Light Pcb Battery Integration

What are the advantages of using LED light PCBs in product integration?

LED light PCBs offer high energy efficiency, long lifespan, and are more durable than traditional lighting solutions. They also provide a more consistent light output and are suitable for a wide range of product integration applications.

How do I determine the appropriate LED light PCB size for my product?

The size of the PCB should be based on the space available within your product and the power consumption of the LED module. It is important to choose a size that fits your product while ensuring that the chosen module provides sufficient illumination.

Can LED light PCBs be customized according to specific requirements?

Yes, many suppliers on Alibaba.com offer customization options for LED light PCBs. You can specify particular sizes, shapes, or additional features to meet the unique needs of your product.

What types of customization can be achieved with LED light PCBs?

LED light PCBs can be customized in terms of size, shape, thickness, and additional features such as waterproofing or sensors that cater to specific product requirements.

Are there waterproof LED light PCBs available for outdoor use?

Yes, you can find LED light PCBs that are specifically designed with waterproofing features for outdoor use. These are typically used in applications like street lighting or garden lighting.

How does the integration process work for LED light PCBs?

The integration process involves incorporating the LED light PCB into the product's design and layout, including ensuring compatibility with existing systems and optimizing the performance of the final product.

What level of technical expertise is required to integrate an LED light PCB into my product?

The level of technical expertise required will depend on the complexity of the integration process. While some systems may be designed for simple plug-and-play, others might require more advanced knowledge of electronics and PCB design.

Can LED light PCBs be integrated into a fully automated process?

Yes, LED light PCBs can be integrated into fully automated processes due to their compact size and ease of use with machine mounting and wiring.

Is it possible to achieve multi-layered LED light PCB designs?

Multi-layered LED light PCB designs are feasible and can offer increased functionality, such as additional circuits or lighting zones. However, they may require more complex manufacturing processes.

What is the expected lifespan of an LED light PCB?

The expected lifespan of an LED light PCB typically ranges from 30,000 to 50,000 hours. However, this can vary based on usage conditions and the quality of the LEDs used.

Are there industry standards for LED light PCBs that I should be aware of?

Yes, there are industry standards like UL (Underwriters Laboratories) that define safety and quality standards for electronic components. It is important to ensure that the selected LED light PCB meets these requirements.

Can I use any type of LED light PCB for my product?

Not all LED light PCBs are suitable for every application. It is essential to select a board that meets the specific environmental conditions and electrical requirements of your product's operation.

How does the number of LEDs on an LED light PCB affect its performance?

The number of LEDs on an LED light PCB affects both the brightness and the dispersion of light. A higher number of LEDs allows for greater coverage area and may be preferable in applications where broader lighting is required.

What is the significance of thermal management in LED light PCB design?

Thermal management is crucial in LED light PCB design because efficient heat dissipation ensures that the LEDs operate within their optimal temperature range, preventing overheating which can reduce their lifespan.