Popular in your industry

Related Searches:

Top categories

About lathe milling machine

Exploring the Versatility of Lathe Milling Machines

Lathe milling machines stand as a testament to the evolution of precision engineering. These machines, integral to shaping and crafting metal components, are pivotal in the manufacturing sector. Their ability to perform various tasks such as cutting, sanding, knurling, and drilling makes them indispensable in the creation of intricate parts.

Types and Applications

The lathe mill combo and mill and lathe combo machines offer a dual functionality that caters to a range of operations. From fashioning symmetrical objects like rings and shafts to fulfilling tasks that require the finesse of a combination mill lathe, these machines are versatile. The lathe and milling machine combo is particularly beneficial in settings where space is at a premium, providing two functionalities within a single footprint.

Technical Features and Materials

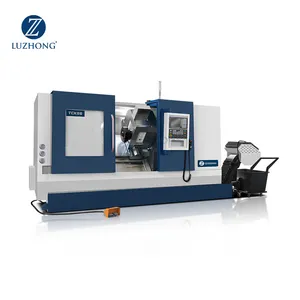

Constructed from robust materials such as metal and FRP, lathe milling machines are designed for sustainability and endurance. The cnc lathe milling machine variants exemplify modern advancements, offering superior precision with their computerized controls. These machines are capable of handling a variety of materials, from metals to leather, showcasing their adaptability across different industries.

Performance and Precision

Performance is at the heart of these machines, with options like the 5 axis cnc mill providing unparalleled precision. The cnc mills and lathes are equipped with features that ensure consistent performance, such as centralized automatic lubrication systems that minimize heat distortion and enhance stability. Furthermore, the integration of low-noise technology ensures that operations are not just efficient but also conducive to a more pleasant working environment.

Design and Customization

The design of lathe milling machines is as varied as their applications, with a range of shapes, colors, and sizes to meet specific needs. While the sherline mill may be ideal for smaller, intricate tasks, larger cnc lathe and milling machine models are available for more demanding projects. These machines are not only functional but also customizable, allowing for specific modifications to meet the unique requirements of different manufacturing tasks.

Environmental Considerations

In an era where sustainability is paramount, the lathe machine milling machine models are designed with eco-friendliness in mind. The durability of the machines reduces waste, and their efficient operation helps in conserving energy. This commitment to environmental considerations ensures that the use of these machines aligns with the growing demand for sustainable manufacturing practices.