Popular in your industry

Related Searches:

Top categories

About hemp string making machine

Hemp String Making Machine: An Overview

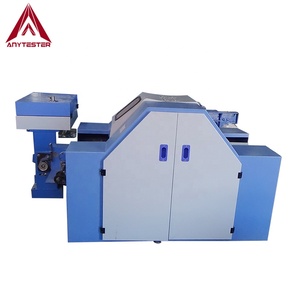

The hemp string making machine stands as a cornerstone in the arena of industrial fiber processing, playing a pivotal role in transforming raw hemp into a versatile and durable string. This machinery is essential for businesses operating within the realms of agriculture, textile, and various industrial sectors, where the production of hemp string is a fundamental process.

Types and Applications

Diverse in its manifestations, the hemp string making equipment ranges from manual to fully automated systems, each designed to meet specific production needs. The applications of these machines are equally varied, catering to the production of hemp ropes, cords, and twines, which are integral to sectors such as packaging, construction, and crafts.

Features and Functionality

The industrial hemp string equipment is engineered to optimize efficiency and durability. With features that allow for adjustable tension, thickness, and length, these machines offer versatility to produce strings that meet different industry standards and requirements. The integration of advanced technology in these machines ensures precision and consistency in production.

Materials and Sustainability

Constructed to withstand the rigors of heavy usage, the hemp twine manufacturing machinery is typically made from robust materials such as high-grade steel. The use of hemp as a raw material promotes sustainability, given its low environmental impact compared to synthetic alternatives.

Advantages of Hemp String

Hemp string boasts numerous advantages, including its biodegradability, strength, and versatility. The hemp cord making machine capitalizes on these traits, enabling producers to fabricate a product that is increasingly sought after in eco-conscious markets.

Choosing the Right Machine

Selecting the appropriate hemp rope making machine hinges on understanding specific production goals and operational capacities. Prospective buyers should consider factors such as output volume, string specifications, and the level of automation required to ensure the acquisition aligns with their operational objectives.