Popular in your industry

Related Searches:

Top categories

About hard plastic block

In an era where sustainability intersects with technology, hard plastic blocks emerge as a cornerstone of innovation and efficiency. These versatile materials, crafted from a myriad of polymers, have transcended their traditional uses to become pivotal in a range of industries, from robust infrastructure projects to intricate consumer goods. This comprehensive guide delves into the multifaceted applications of hard plastic blocks, exploring their properties, types, and the transformative role they play in maximizing efficiency across various sectors.

Understanding Hard Plastic Blocks

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes them suitable for molding into solid objects of various shapes, making them ideal for producing hard plastic blocks. The history of plastic dates back to the 19th century, but it's the advancements in chemical engineering that have allowed for the diverse types of plastics we see today.

Hard plastic blocks are typically made from materials such as Polyethylene Terephthalate (PET), known for its strength and recyclability, Acrylonitrile Butadiene Styrene (ABS), which offers good resistance to physical impacts and chemical corrosion, and Polyvinyl Chloride (PVC), valued for its durability and ease of use. These materials give hard plastic blocks their characteristic properties such as lightweight, resistance to chemicals, and insulating properties.

Understanding the characteristics of plastics is crucial when considering hard plastic blocks for any application. These blocks exhibit a range of properties including durability, flexibility, and resistance to moisture, chemicals, and weathering. The versatility of plastic materials means that hard plastic blocks can be tailored to meet specific needs in various applications, from construction to the design of consumer goods.

Types of Hard Plastic Blocks on Alibaba.com

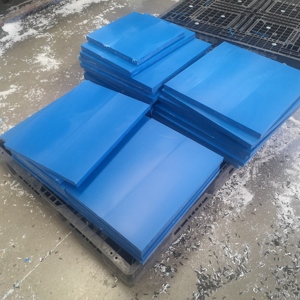

Alibaba.com showcases a diverse range of hard plastic blocks, tailored for various applications and industries. Among the selection, HDPE (High-Density Polyethylene) blocks are prominent, known for their durability and non-toxic properties, making them suitable for outdoor and cooling applications. The platform also features thermoforming HDPE sheets, boards, and panels, which are direct from manufacturers, ensuring cost-effectiveness for bulk purchases.

Customization options are abundant, with suppliers offering hard plastic blocks in various colors and sizes, catering to specific engineering requirements. Materials such as PP (Polypropylene), UHMWPE (Ultra High Molecular Weight Polyethylene), and HDPE are available, providing a range of mechanical and chemical properties to suit different engineering needs. For precision tasks, CNC machined blocks made from materials like polypropylene and ABS (Acrylonitrile Butadiene Styrene) are available, which are ideal for detailed and high-strength applications.

The inventory includes specialized blocks such as POM (Polyoxymethylene) Acetal, known for its low-friction and high-stiffness characteristics. For applications demanding high wear resistance, nylon blocks are offered, which stand up well to abrasion. The platform also lists polyurethane blocks, which are impact-resistant, and PEEK (Polyether Ether Ketone) blocks that provide high-temperature resistance, catering to advanced engineering applications.

For construction and paving, hard plastic bricks and pavers mould blocks are available, which are designed for creating standard-size bricks. These products highlight the versatility of hard plastic blocks, demonstrating their utility in both industrial and commercial settings. The range of thicknesses and sizes available ensures that businesses can find the right type of hard plastic block to meet their specific requirements.

Common Applications of Hard Plastic Blocks

Hard plastic blocks, such as those created from recycled plastics, are increasingly being utilized in infrastructure projects. These blocks are part of a growing trend to incorporate post-consumer plastics into construction materials, contributing to more durable and sustainable roads. The versatility of plastic road technologies is evident as they are being mixed with asphalt to reinforce roads, making them last longer and reducing maintenance needs. This innovative approach is not limited to asphalt but extends to concrete applications, where plastic additives can create lighter yet equally strong materials.

These materials are being used to enhance the durability of roads, leading to cost savings in road construction and maintenance. Additionally, the use of hard plastic blocks in roadways is an environmentally beneficial practice, as it provides an end-of-life solution for plastics that might otherwise end up in landfills.

Beyond road construction, hard plastic blocks are finding their way into other areas of infrastructure. These blocks can be used in a variety of building applications, showcasing the adaptability and potential of hard plastic blocks to revolutionize the construction industry and contribute to a more circular economy.

Features and Benefits of Using Hard Plastic Blocks

Rigid plastics are renowned for their protective qualities, offering a robust barrier against external elements. This characteristic ensures that products, ranging from food items in clamshell containers to electronics in cell phone packaging, are delivered in pristine condition. The durability of these materials is a key feature, contributing to their longevity and reliability.

The versatility of rigid plastics is evident in the variety of substrates available. Manufacturers can utilize substrates such as PET and HDPE, which are selected based on cost-effectiveness and suitability for the product's requirements. This adaptability extends to the array of shapes that can be achieved through custom thermoforming molds, allowing for both common and unique packaging designs that can differentiate products in the marketplace.

An additional advantage of rigid plastics is their improved recyclability. Advances in recycling processes have expanded the types of rigid plastics that can be recycled, enhancing their sustainability profile. This progress in recycling capabilities aligns with increasing environmental consciousness and initiatives by cities to incorporate such materials into their recycling programs.

Material Specifications and Durability

Hard plastic blocks are crafted from a variety of durable materials, each with unique specifications contributing to their longevity and performance. Acrylic or Polymethyl Methacrylate (PMMA) is a transparent thermoplastic, known for its lightweight and shatter-resistant properties, making it a robust alternative to glass. Polycarbonate (PC) is another transparent material but is significantly stronger than acrylic, offering 250 times the strength of glass, which is beneficial for high-impact applications.

Polyethylene (PE) comes in various densities, with each providing different characteristics. High-Density Polyethylene (HDPE) is noted for its rigidity and is used in products that require a sturdy but flexible material. Ultra-High Molecular Weight Polyethylene (UHMWPE) stands out for its extreme abrasion resistance and low friction, making it suitable for high-wear applications.

Polypropylene (PP) is a versatile thermoplastic polymer that retains flexibility under stress and is resistant to many chemical solvents, bases, and acids. Polyethylene Terephthalate (PET) is known for its excellent chemical resistance and high strength-to-weight ratio. Polyvinyl Chloride (PVC) can be tailored to be either rigid or flexible, and its ability to blend with other materials makes it a versatile choice for various applications. Lastly, Acrylonitrile-Butadiene-Styrene (ABS) combines toughness with flexibility and is easily processed, suitable for a wide range of thicknesses and applications.

Maximizing Efficiency with Hard Plastic Blocks

Recycled plastic construction blocks present an innovative solution in the realm of construction materials, utilizing recycled plastic. These blocks are a testament to sustainable practices, transforming hard-to-recycle plastic into functional building materials. Each block's dimensions and weight signify its robustness, suitable for various construction needs.

The manufacturing process of these construction blocks is noteworthy for its eco-friendly approach, ensuring that the plastic used is completely converted into blocks without excess waste. This efficient use of materials not only addresses waste management issues but also offers a durable alternative to traditional construction blocks.

The design of these blocks allows for straightforward installation, comparable to conventional concrete blocks, but with the added benefit of not requiring adhesives. This feature simplifies the construction process and enhances the efficiency of building projects. Moreover, the durability of these blocks is evident as they are engineered to resist cracking and crumbling, common issues with traditional cinderblocks.

Innovative Uses in Various Industries

Polypropylene, a versatile thermoplastic, has found its way into various industries due to its unique properties. In the automotive sector, it's utilized for components like battery casings, trays, drink holders, bumpers, interior details, instrumental panels, and door trims. Its resilience to chemical corrosion and fatigue makes it a preferred choice for these applications. The marine industry benefits from its waterproof nature, employing polypropylene in products such as ropes, twine, and fishing nets. Moreover, its resistance to moisture absorption and durability against mildew and rot enhances its suitability for outdoor and marine applications.

The material's adaptability extends to the medical field, where its resistance to bacteria and mold, coupled with the ability to withstand steam sterilization, makes it valuable for medical components. Polypropylene's insulation properties are also advantageous in electrical goods and cables, providing safety and durability. Furthermore, its flexibility and high flexural strength allow it to be used in demanding physical environments, making it an ideal choice for various industrial applications where robustness is required.

Choosing the Right Hard Plastic Block for Your Needs

When selecting the appropriate hard plastic block for specific needs, it's crucial to consider the material's properties and the application's requirements. Acrylic blocks, known for their clarity and strength, can be an excellent choice for projects demanding visual appeal and durability. They are resistant to UV damage and scratches, making them suitable for both indoor and outdoor applications such as advertising displays and marine windshields.

For environments where impact resistance is paramount, polycarbonate blocks offer a robust solution. With a strength that significantly surpasses glass, these blocks serve well in areas prone to harsh conditions, such as storefronts, protective coverings, and in the marine industry. They can also be treated for UV resistance, adding to their versatility.

Each type of hard plastic block comes with its unique set of features. Acrylic blocks, for instance, are available in various colors and can be lit to create eye-catching signage. Polycarbonate blocks, on the other hand, are known for their thermal insulation properties, making them ideal for applications like greenhouses. When choosing a block, consider factors such as resistance to abrasion, UV stability, and compliance with safety standards like flame retardancy and food safety when applicable.

Ultimately, the decision should be guided by the specific needs of the project, balancing factors such as cost, durability, and the aesthetic requirements of the application. By carefully assessing these criteria, one can select a hard plastic block that not only meets the functional demands but also contributes to the efficiency and effectiveness of the end product.

Conclusion

Hard plastic blocks represent a fusion of durability, versatility, and sustainability, serving as a testament to human ingenuity in material science. From the robust alternatives to traditional concrete to the intricate components in automotive and medical industries, these materials stand at the forefront of innovation. As we have seen, the selection of the right hard plastic block—be it acrylic for visual appeal or polycarbonate for impact resistance—can significantly influence the efficiency and success of a project. The guide has illuminated the importance of considering factors such as UV stability, abrasion resistance, and safety standards in making an informed choice. In conclusion, hard plastic blocks are not just materials; they are enablers of a more efficient, sustainable future, driving industries forward while conscientiously addressing environmental concerns.