Popular in your industry

Related Searches:

Top categories

About gold production line

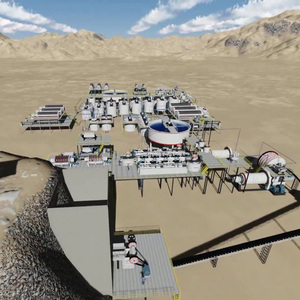

The gold production line is a system that processes gold ore to extract the precious metal in a series of steps. The main equipment involved in this line is the ball mill, flotation machine, leaching tank, thickener, and other significant devices. To start with, the gold ore is initially broken down into smaller pieces, which is usually done by a crusher. This broken ore is then fed into a ball mill, which grinds the ore into a fine powder. Once the ore is ground down, it is then mixed with water and other chemicals in a flotation machine. This process helps to separate the gold from the other minerals and impurities in the ore.

Furthermore, the leaching tank is used to dissolve the gold from the powdered ore using a cyanide solution. This creates a gold-cyanide complex, which is then absorbed onto activated carbon in a process known as carbon-in-leach. The next step involves the thickener, which is used to separate the solid gold particles from the liquid. The solid gold particles are then sent to a smelter, where they are melted down and cast into ingots. Meanwhile, the liquid, which contains other minerals and impurities, is sent to a refinery for further processing. This refinery may use techniques such as electrowinning or the thrive gold line fortify process to extract the gold from the solution.

In addition, to the goldline pet foods, the final step in the gold production line is the refining process. The gold ingots are melted down and cast into bars, which are then sent to a refinery for further processing. This refinery may use techniques such as electrowinning or the goldline foods process to extract the gold from the solution. Once the gold has been refined to the desired purity, it is then cast into bars or other shapes and is ready to be sold in the market.

Advantages of the Gold Production Line

One of the advantages of the gold production line is its efficiency. The use of modern equipment and technological advancements in the mining industry has made the process of extracting gold from ore faster and more cost-effective. This increased efficiency not only reduces the time it takes to extract gold but also lowers the overall operating costs of the operation. Moreover, the process is more environmentally friendly. The gold line feeds have incorporated technologies such as cyanide detoxification to minimize the environmental impact of the production line. The use of these technologies ensures that the extraction of gold from ore is done in a way that is sustainable and aligns with modern environmental standards.

Another key advantage is the ability to handle complex gold ores. The gold production line is designed to process a wide range of gold ore types, including refractory ores that contain gold that is not readily extractable. The inclusion of various steps and specialized equipment in the production line allows for the efficient processing of these complex ores, resulting in the recovery of gold that might have been previously challenging to extract. Lastly, the gold production line offers consistency in the quality of the final gold product. The use of standardized processes and technologies in the production line ensures that the gold produced meets the desired purity and quality standards. This consistency is essential, especially in industries such as jewelry making and electronics manufacturing, where the quality of gold is a critical factor.