Popular in your industry

Related Searches:

Top categories

About electrical plug mould

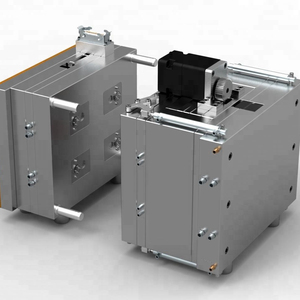

Introduction to Electrical Plug Moulds

Electrical plug moulds are essential components in the manufacturing of plug inserts used in various electrical connectors. These precision tools are designed to shape and solidify materials into functional electrical plugs through a process known as injection molding. The versatility of these moulds allows for the production of plugs that meet diverse industry standards and specifications.

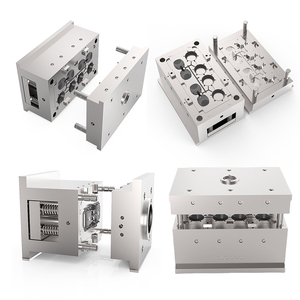

Types and Applications

The application of electrical plug moulds spans across various industries, from consumer electronics to industrial power systems. The types of moulds vary, including single-cavity for bespoke projects and multi-cavity for high-volume production. Each mould type is tailored to produce plugs that are compatible with different electrical systems and standards, ensuring connectivity and safety across devices and power sources.

Material and Design Considerations

When selecting an electrical plug mould, material choice is critical. Options range from hardened steel to aluminum, each offering distinct advantages in terms of durability and thermal conductivity. The design process involves precision engineering to ensure that the final product meets exacting tolerances and fits seamlessly within its intended electrical system.

Features and Advantages

Modern electrical plug moulds are engineered to maximize efficiency and lifespan. Features such as self-cleaning mechanisms and corrosion-resistant coatings contribute to their longevity and reliability. The advantage of using a standardized mould includes consistency in production and compatibility with existing manufacturing systems, leading to reduced downtime and increased productivity.

Optimizing Production with Mould Standardization

Manufacturers can optimize their production processes by standardizing certain elements of their electrical plug moulds. This includes uniform lift bars, connection sizes, and clamp slots, which facilitate interchangeability and ease of use across various moulding machines. Such standardization can lead to significant cost savings and operational efficiencies.

Selecting the Right Mould for Your Needs

Choosing the appropriate electrical plug mould involves careful consideration of the design, material, and specific application. Suppliers on Alibaba.com offer a diverse range of moulds to meet these needs, providing detailed information to assist buyers in making informed decisions. By leveraging the platform's resources, buyers can find moulds that align with their production requirements and quality standards.