Popular in your industry

Related Searches:

Top categories

About custom injection mold plastic drawer

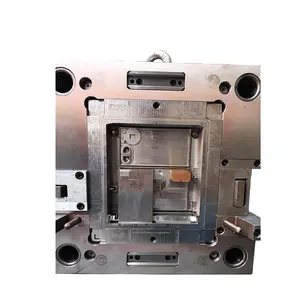

Introduction to Custom Injection Molded Plastic Drawers

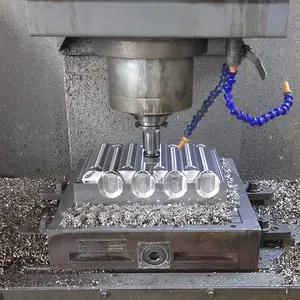

Injection molding is a versatile manufacturing process used for producing custom injection mold plastic drawers in high volumes. These drawers are crafted through a process where molten plastic is injected into a pre-designed mold, solidifying into the desired shape. This method is ideal for creating durable and uniform products suitable for various organizational and storage needs.

Types and Applications

The applications of injection molded drawers are extensive, ranging from industrial parts storage to office organization systems. They can be designed to fit specific dimensions and purposes, such as tool storage in workshops or document organization in offices. The adaptability of the plastic drawer mold process allows for the creation of custom solutions tailored to the needs of businesses across different sectors.

Material Selection and Features

Material choice is critical in the production of plastic drawers. Options include various plastics like ABS, polyethylene, and polycarbonate, each offering distinct characteristics in terms of strength, flexibility, and resistance to impact and chemicals. The selection of material affects the drawer’s durability, functionality, and appearance. Features such as stackability, load capacity, and resistance to environmental factors can be integrated into the design, depending on the chosen material.

Advantages of Customization

Customization is a significant advantage when opting for injection molded plastic drawers. It allows for the optimization of space, the incorporation of company branding, and the adjustment of drawer dimensions to specific requirements. Furthermore, the ability to standardize components like lift bars and clamp slots can streamline the manufacturing process and enhance compatibility with existing systems.

Ensuring Product Satisfaction

Choosing the right provider for plastic injection mold services is crucial. Suppliers on Alibaba.com collaborate with clients to refine mold designs, ensuring the final product meets their specifications. This collaborative approach often includes the production of test samples to confirm the mold’s precision and the product’s functionality before full-scale manufacturing commences.

Streamlining Production Costs

Investing in a custom plastic drawer mold can lead to cost efficiencies in the long run. By standardizing certain mold elements, businesses can reduce production times and costs, while maintaining consistency across multiple product lines. This strategic approach to mold design can significantly benefit businesses looking to optimize their manufacturing processes.