Understanding Crankshaft Straightening Presses

A crankshaft straightening press is an essential tool in the realm of metalworking and automotive repair, designed to rectify bends and deformities in crankshafts. This category of machinery is pivotal for ensuring the proper functioning of engines, where precision is non-negotiable.

Types and Configurations

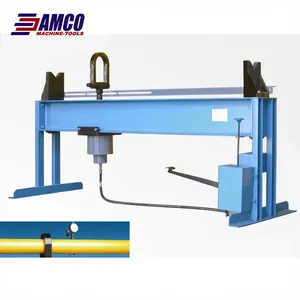

The versatility of a hydraulic crankshaft press is evident in its various tonnages and sizes, catering to diverse operational requirements. From bench-top models suitable for smaller tasks to robust floor-standing units, these presses are engineered to deliver the necessary force for straightening tasks. The frame construction, whether an adjustable H-frame or a fixed C-frame, plays a crucial role in the press's functionality and suitability for specific applications.

Features and Applications

The industrial crankshaft press is not just about power; it's also about adaptability. With adjustable bolsters, these presses can accommodate workpieces of varying sizes, making them indispensable for tasks such as stamping, bearing work, or bending. The inclusion of accessory plates and other add-ons like dwell timers and pressure reversal switches enhances the functionality of these presses, making them a go-to solution for precision straightening.

Materials and Construction

Durability is at the core of a crankshaft repair press. The construction involves robust materials capable of withstanding high pressure without compromising performance. Springs integrated into the frame add a layer of flexibility, essential for managing the intense forces during operation.

Advantages of Utilizing a Crankshaft Straightening Press

The primary advantage of using a crankshaft straightening machine lies in its ability to restore the crankshaft's functionality, which is critical for engine performance. The precision that these machines offer ensures that the straightening process does not compromise the integrity of the crankshaft, thereby extending its service life.

Selecting the Right Press for Your Needs

When in the market for a crankshaft press, it's essential to consider the specific requirements of your tasks, including the size of the workpiece and the degree of pressure needed. The flexibility of the piston movement, bolster space, and the type of frame are all critical factors to ensure you select a press that aligns with your operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4