Popular in your industry

Related Searches:

Top categories

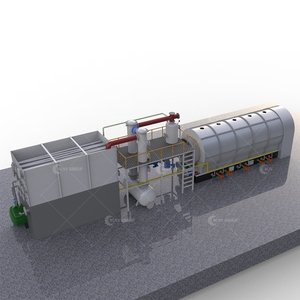

About converting plastic to fuel

Converting plastic into fuel is an innovative technology that addresses the growing concern of plastic pollution while offering a sustainable solution for energy production. The process involves the thermal breakdown of plastic waste to produce fuel in the form of oil, gas, or diesel. This plastic to fuel conversion represents an important advancement in waste management and renewable energy. Not only does it help in reducing the environmental impact of plastic waste, but it also provides an alternative source of energy.

Types of Converting Plastic into Fuel

There are different methods of turning plastic into fuel. One commonly used approach is pyrolysis, where plastic is heated in the absence of oxygen to break down the long-chain polymers into smaller hydrocarbons. This process yields a mixture of gases, liquid fuel, and solid residue. Another method is catalytic depolymerization, which involves using a catalyst to accelerate the breakdown of plastic into fuel components. Gasification is also utilized, wherein plastic is converted into a synthesis gas, or syngas, which can be further processed to produce fuels like methanol and diesel. Additionally, some technologies employ solvolysis, a process that utilizes solvents to break down plastic into fuel.

Business Value of Converting Plastic into Fuel

The conversion of plastic into fuel has significant business value. For waste management companies, the technology offers a cost-effective solution for dealing with plastic waste that may otherwise be challenging to recycle. By converting plastic waste into fuel, these companies can not only reduce the volume of waste but also create a valuable product. Additionally, the production of fuel from plastic aligns with the growing demand for sustainable practices, providing businesses with a competitive edge in terms of environmental responsibility. Furthermore, the fuel produced from plastic can be used in various industries, including transportation and manufacturing, offering a versatile energy source. For entrepreneurs and investors, the plastic-to-fuel technology represents an opportunity to contribute to environmental conservation while exploring innovative energy solutions.

Advantages of Converting Plastic into Fuel

The process of converting plastic into fuel offers several advantages. Firstly, it provides an effective solution for managing plastic waste, reducing the burden on landfills and the environment. By transforming plastic into fuel, the technology contributes to the circular economy and resource efficiency. It also helps in addressing the issue of plastic pollution, as it offers an alternative to the traditional methods of disposal. Secondly, the fuel derived from plastic is a valuable energy source that can be utilized in various applications, including power generation and transportation. This versatility enhances the economic viability of the technology. Additionally, the process of converting plastic into fuel can lead to a reduction in greenhouse gas emissions, as it provides a cleaner alternative to conventional fossil fuels.