Popular in your industry

Related Searches:

Top categories

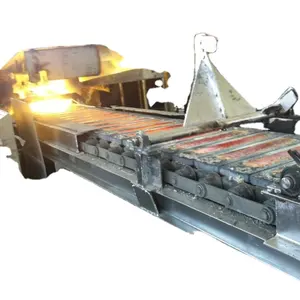

About continuous casting machine billet

In the realm of the steel industry, the steel billet continuous casting machine represents a critical piece of equipment for the efficient and continuous production of steel billets. This machine plays a pivotal role in the casting process, providing a streamlined method for transforming molten steel into solid billets of specific shapes and sizes. The process involves the controlled solidification of steel within a water-cooled mold, ensuring the production of high-quality billets with minimal need for subsequent processing. The billet caster machine's ability to deliver a continuous output of steel billets makes it an essential component in various sectors, ranging from construction to manufacturing.

The working principle of the continuous casting machine for steel billets

The operating principle of the continuous casting machine for steel billets revolves around the steady and uninterrupted transformation of molten steel into solid billets. It begins with the heating of raw materials in a furnace, melting them into a liquid state. The molten steel is then transferred to the tundish, a refractory-lined reservoir that acts as a buffer and controls the flow of steel to the billet continuous casting machine.

The actual casting process takes place within the machine's water-cooled mold. The tundish supplies a continuous flow of molten steel, which enters the mold through a submerged entry nozzle (SEN). As the steel flows into the mold, it begins to solidify along the inner surfaces, gradually forming the shape of the desired billet. The controlled cooling provided by the water-cooled walls of the mold is crucial in ensuring the uniform solidification of the steel. As the partially solidified billet exits the mold, it passes through a series of secondary cooling zones, such as spray chambers or air-mist cooling devices, which further enhance its structural integrity.

The advantages of the continuous casting machine for the steel billet

The continuous casting machine billet offers a host of advantages over traditional batch casting processes, making it a preferred choice for steel billet production. Continuous casting significantly reduces the need for subsequent processing steps, such as rolling or forging, which are often required for billets produced through conventional methods. This leads to higher material utilization and lower energy consumption, contributing to overall cost savings. Additionally, the controlled solidification process of continuous casting results in a more uniform microstructure and improved mechanical properties in the final billet. This leads to enhanced product quality, making continuous-cast steel billets preferable for critical applications in industries like automotive and aerospace.

The continuous nature of the process also allows for better process control and the production of customized billet sizes, catering to diverse market demands. Furthermore, the continuous casting machine for steel billets minimizes material waste, as it can effectively use various steel grades and recycle scrap metal, aligning with sustainable production practices. The combination of efficiency, quality, and environmental benefits positions the billet caster machine as a cornerstone in modern steel manufacturing, meeting the needs of industries that rely on high-performance and consistently shaped steel products.