Popular in your industry

Related Searches:

Top categories

About cone thread winding machine

Introduction to Cone Thread Winding Machines

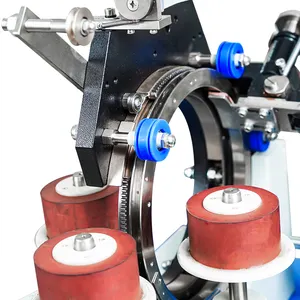

The cone thread winding machine is an essential device designed to enhance efficiency in the production of coils for various electrical appliances. This machine is pivotal in workshops and manufacturing settings, streamlining the process of winding threads onto cones, which is a critical step in creating solenoids and transformers.

Types and Applications

There are several types of thread winding equipment, including the sewing thread cone winding machine and the thread cone winder machine. Each serves a specific function, from heavy-duty industrial use to more delicate sewing applications. These machines are employed in the production of electrical fans, transformers, and other appliances requiring coiled components.

Operational Features

The operational features of a cone thread winder are designed for ease of use and efficiency. Options range from fully automated systems to semi-automatic and manual machines, each providing a different level of control and precision. Automated winders, in particular, offer a significant reduction in manual labor and an increase in production accuracy.

Materials and Construction

Constructed to meet diverse industrial demands, these machines are built with robust materials that ensure durability and consistent performance. The mechanical components are designed to handle various thread types and weights, ensuring versatility across different manufacturing needs.

Advantages of Utilizing Cone Thread Winders

Utilizing a cone thread winding machine in your production line can lead to increased productivity by minimizing the time spent on coil winding tasks. These machines are engineered to produce tightly wound, consistent coils with minimal oversight, reducing the potential for human error and the need for rework.

Ensuring Quality and Maintenance

Quality is a cornerstone of these machines, with many meeting international production standards. While they are designed for low maintenance, guidelines are provided to ensure proper care and extend the lifespan of the equipment. Technicians can demonstrate the correct operation of the machines to ensure optimal performance.

Incorporating a cone thread winding machine into your manufacturing process can be a strategic move to enhance productivity. With a variety of models available on Alibaba.com, businesses can select the appropriate machine that aligns with their operational needs and production goals.