Related Searches:

Top categories

About cnc machine for pcb board

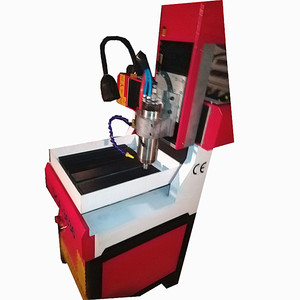

CNC Machine for PCB Board: An Overview

The realm of precision manufacturing has been revolutionized by the advent of CNC machines for PCB boards, offering unparalleled accuracy and efficiency in the production of printed circuit boards (PCBs). These sophisticated devices cater to the intricate processes of milling, drilling, and cutting, which are integral to the creation of PCBs used in various electronic devices.

Types and Applications of CNC PCB Equipment

The versatility of CNC PCB milling machines is evident in their various forms, including the cnc pcb board routers and the more specialized cnc circuit board mill units. Each type serves a specific purpose, from creating detailed circuit designs to mass-producing electronic components. The application of these machines spans across industries, from consumer electronics to aerospace, where precision and reliability are paramount.

Features and Materials in CNC PCB Production

A cnc machine for pcb fabrication is designed to handle a multitude of materials, ranging from standard FR-4 to more advanced metal-clad substrates. The features of these machines, such as variable spindle speeds, advanced control systems, and precision collets, contribute to their ability to produce PCBs with intricate layouts and tight tolerances. The pcb cnc milling machine models, in particular, are equipped with features that facilitate the removal of copper layers, allowing for the creation of complex circuit patterns.

Advantages of Utilizing CNC for PCB Milling

The use of cnc pcb milling technology in PCB production brings forth numerous advantages, including improved accuracy and repeatability, which are crucial for electronic components. The automation capabilities of a pcb cnc machine also lead to increased production speeds and reduced waste, making the manufacturing process more cost-effective and environmentally friendly.

Choosing the Right CNC Machine for PCB Design

Selecting the appropriate cnc machine for pcb design requires a thorough understanding of the specific needs of the project. Factors such as the complexity of the PCB design, the volume of production, and the type of material being used are critical considerations. For hobbyists or small-scale operations, a diy cnc pcb setup might be sufficient, while larger-scale productions may necessitate a more robust and automated solution like a pcb board cnc machine.

Integrating CNC PCB Maker into Your Workflow

Incorporating a cnc pcb maker into a manufacturing workflow can streamline the production process, from prototype to final product. With the ability to quickly and accurately produce PCBs in-house, businesses can reduce turnaround times and adapt swiftly to design changes, maintaining a competitive edge in the fast-paced electronics market.