Introduction to Carbon Fiber Manufacturing Equipment

Carbon fiber manufacturing machines are pivotal in the production of carbon fiber composites, known for their strength-to-weight ratio and durability. These machines are integral to various industries, including aerospace, automotive, and sports equipment manufacturing. The technology behind these machines is constantly evolving, offering improved efficiency and quality in carbon fiber production.

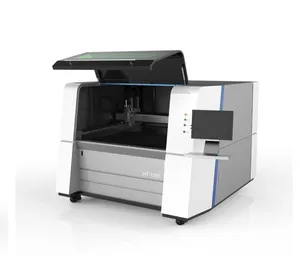

Types of Carbon Fiber Manufacturing Machines

The carbon fiber production process typically involves two main types of machines: single screw and double screw extruders. Single screw carbon fiber machines are suitable for operations with modest production requirements. In contrast, double screw extruders are recognized for their enhanced efficiency, effectively increasing output due to their dual-screw design. The choice between these types hinges on the specific production demands and capacity requirements of the operation.

Applications and Features

Carbon fiber manufacturing equipment is versatile, catering to a range of applications from industrial to commercial uses. These machines are designed to handle various forms of carbon fiber, adapting to different manufacturing processes. Key features include low thermal conductivity and a minimal coefficient of thermal expansion, ensuring the material retains its shape under thermal stress. Additionally, the durability of carbon fibers means that products maintain their integrity over time, reducing the need for frequent replacements or repairs.

Materials and Advantages

The construction of carbon fiber production machinery involves materials that can withstand the rigorous processes of carbon fiber production. The advantages of using such equipment are manifold. Notably, carbon fibers' ability to absorb toxins and gases makes them beneficial for environmental conservation. Furthermore, their sound dampening properties are advantageous in creating quieter production environments.

Environmental Impact and Durability

Carbon fiber processing equipment is designed with sustainability in mind. The production process is geared towards minimizing environmental impact, with carbon fibers themselves being excellent at gas absorption. The inherent strength of carbon fiber atoms contributes to the machines' longevity, ensuring that they can withstand the demands of continuous manufacturing cycles without compromising performance.

Choosing the Right Machine

Selecting the appropriate carbon fiber manufacturing machine is crucial for any operation. Factors to consider include production volume, the specific application of the carbon fiber, and the desired features of the end product. While the initial investment in these machines can be significant, the long-term benefits of durability, efficiency, and product quality offer a return on investment that is worth considering for any business in the field of carbon fiber production.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4