Popular in your industry

Related Searches:

Top categories

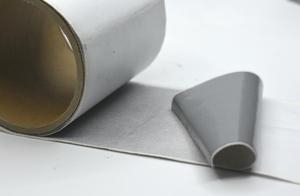

About butyl rubber waterproofing membrane

Introduction to Butyl Rubber Waterproofing Membrane

The butyl rubber waterproofing membrane category encompasses a range of products designed for protective sealing in various applications. This membrane is a preferred choice for its exceptional adhesive properties and resistance to weathering, making it ideal for sealing in construction and industrial settings.

Types and Applications

There are several types of butyl rubber sheet waterproofing solutions, each suited to different applications. From window and door seals to marine industry applications, these membranes provide a durable barrier against moisture and air. In construction, butyl sheet waterproofing is often used to create water-resistant surfaces on roofs, basements, and walls.

Features and Materials

Butyl rubber waterproofing membrane is known for its flexibility and resilience. The material can be either non-recycled or recycled, catering to a range of environmental and budgetary preferences. Its versatility extends to both rigid and flexible forms, allowing for use on various surfaces and in different conditions.

Advantages of Butyl Rubber Membranes

The primary advantage of butyl rubber waterproofing is its impermeability to water, providing reliable protection in moisture-prone areas. Additionally, its flexibility makes it suitable for spaces that experience movement or require a snug fit, such as on boats or in uniquely shaped rooms.

Color and Design Variations

Aesthetic versatility is another benefit, with butyl rubber waterproofing membrane available in a spectrum of colors to match various design needs. Options range from teak-like appearances for a natural wood effect to sleek black for modern designs, ensuring a cohesive look in any setting.

Choosing the Right Membrane

Selecting the appropriate butyl rubber waterproofing membrane involves considering the application's specific requirements, such as the need for flexibility or rigidity and the desired aesthetic outcome. With a variety of options available, finding the right fit for any project is streamlined.