Popular in your industry

Related Searches:

Top categories

About burnt clay brick making machine

Introduction to Burnt Clay Brick Making Machines

The burnt clay brick making machine stands as a cornerstone in the field of industrial construction equipment, designed to meet the demands of brick production. This category encompasses a variety of machines tailored to fabricate bricks through the process of compressing and heating clay. The significance of these machines lies in their ability to produce a fundamental building material: the burnt clay brick, which has been a staple in construction for centuries.

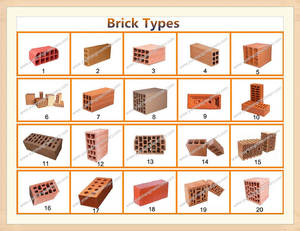

Types of Brick Making Machinery

Diverse types of machinery cater to different brick making requirements. For example, the automatic brick making machine streamlines production with minimal manual intervention, while the manual brick making machine offers a more hands-on approach, often preferred in smaller scale operations. Additionally, the hydraulic brick making machine is known for its robust performance, particularly in mass production settings. Each type serves a specific purpose, ensuring that a variety of production needs are met.

Applications and Features

The application of a burnt clay brick making machine extends across the construction industry, from residential buildings to commercial infrastructures. These machines boast features such as precision molds and advanced heating systems that ensure uniformity and strength in the bricks produced. Furthermore, the brick extruder machine is another variant that shapes clay into bricks with high efficiency, making it a valuable asset in large-scale production.

Materials and Advantages

Burnt clay brick machinery operates using various raw materials, primarily different types of clay and shale. These materials are advantageous due to their widespread availability and cost-effectiveness. The end product, burnt clay bricks, are lauded for their durability and thermal insulation properties, making them a preferred choice for many construction projects.

Choosing the Right Machine

Selecting the appropriate brick manufacturing equipment involves considering factors such as production capacity, brick size, and shape requirements. It is crucial to assess the specifications of each machine to ensure it aligns with the project's needs. For those seeking to produce specialized bricks, such as interlocking bricks, machines designed for this purpose are also available, highlighting the versatility of the equipment found on Alibaba.com.

Complementing Your Brick Making Operations

In addition to the primary machinery, complementary equipment can enhance the brick making process. This includes brick cutting machines and transport vehicles, which aid in shaping the bricks to precise dimensions and facilitating their movement to construction sites. Integrating these tools can lead to a more streamlined and efficient production line.