Mould Temperature Controller Overview

A mould temperature controller (MTC) is a pivotal component in the realm of industrial manufacturing, designed to maintain the temperature of a mould at a predetermined level. This precision instrument is critical in various sectors, including the rubber, die-casting, food, and flat mold industries. By regulating the mould temperature, these controllers ensure consistent quality and optimal processing conditions.

Types and Applications

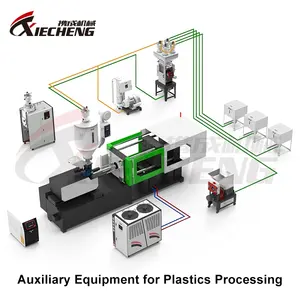

The applications of mould temperature controllers are diverse, with specific types tailored for different industrial needs. The mold temperature controller oil type is suited for high-temperature applications, while water-based controllers are used for moderate temperature ranges. These devices are integral to processes such as injection moulding, where the temperature control unit for injection molding plays a crucial role in the production of intricate shapes and designs.

Features and Advantages

Modern mould temperature controllers boast features like microcomputer touch control, which simplifies operation and enhances efficiency. The dual heating pipes in these controllers allow for precise temperature adjustments, contributing to energy conservation and resource optimization. Additionally, the integration of smart digital temperature controllers ensures rapid heating and cooling, which is essential for maintaining production momentum and reducing the incidence of defective products.

Materials and Durability

Durability is a key factor in the design of mould temp controllers. Many units incorporate stainless steel tube heaters, which are resistant to rust and scaling, thereby extending the lifespan of the equipment. This robust construction ensures that the mould temperature controller can withstand the rigors of continuous industrial use.

Technological Integration

The advent of technology in the field of mould temperature control has led to the development of advanced systems like the shini stm mould temperature controller. These systems are equipped with automatic start-up and exhaust functions, and they display real-time inlet and outlet water temperatures. The fault display feature is particularly beneficial for maintenance purposes, allowing for quick troubleshooting without the need for professional intervention.

Choosing the Right Controller

Selecting the appropriate mould temperature controller is crucial for any industrial operation. Factors such as the mould temperature controller price, working principle, and specific industry application must be considered to ensure optimal performance. While Alibaba.com does not endorse any particular brand or model, the platform offers a wide array of options to cater to the varied requirements of industrial buyers.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4