Popular in your industry

Related Searches:

Top categories

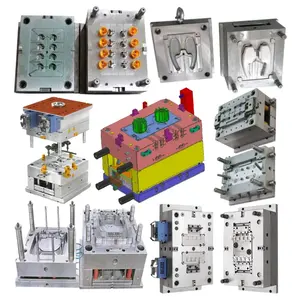

About 5 gallon cap injection mold machine

Introduction to 5 Gallon Cap Injection Mold Machines

The realm of plastic manufacturing is revolutionized by the advent of 5 gallon cap injection mold machines, a category that stands as a cornerstone in the packaging industry. These machines are meticulously engineered to cater to the production of caps, specifically designed for 5-gallon containers—a common necessity across various sectors.

Technical Specifications and Applications

Understanding the technical prowess of these machines is crucial for potential users. The injection molding equipment is equipped with a specialized screw that enhances plasticizing capabilities, ensuring efficient shot weights and speeds. The clamping force, a critical aspect of these machines, ranges significantly to accommodate different manufacturing requirements, making them versatile for producing thin wall containers, caps, pails, and buckets. Their application is widespread, serving industries from consumer electronics to food and beverage, each benefiting from the precise dimensions these machines can achieve.

Design and Durability Features

The design of a 5 gallon cap injection molding machine is a testament to durability and efficiency. The steel bush in the clamping unit is innovatively structured to minimize wear resistance, which in turn reduces the need for frequent lubrication, indirectly cutting down operational costs. The single-cylinder system with a servo-valve ensures a consistent response rate during the molding process, which is crucial for maintaining production momentum.

Advantages of Modern Molding Tools

Modern plastic injection molders are not just about performing the task at hand; they are about enhancing it. With constant design improvements, these machines are tailored for high-speed operations without compromising on the quality of the output. The precision of the end product is a significant advantage, as it reduces the likelihood of defective rates, a concern for any mass production line.

Material Handling and Precision

Precision in material handling is another forte of the cap molding machine. From accepting plastic granules to shaping them into precise dimensions, the process is a blend of accuracy and finesse. This precision is further augmented by the machine's ability to resist external machining forces, ensuring that the end product meets the industry standards of quality and dimension.

Choosing the Right Machine

Selecting the right injection molding machine is pivotal for businesses looking to invest in their production capabilities. The machines on Alibaba.com are specialized for different sizes of preforms, allowing for a tailored approach to production needs. The special design ensures that businesses invest in the exact clamping force required for their specific operations, optimizing both cost and production efficiency.