Popular in your industry

Related Searches:

Top categories

About 3 in 1 busbar machine

Exploring the Triple-Function Busbar Machine

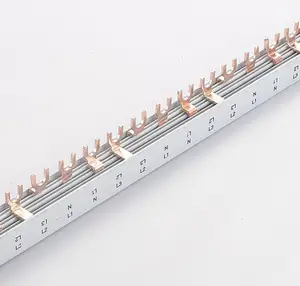

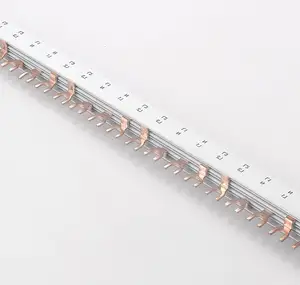

Triple-function busbar machines are precision-engineered to process busbars, integral components in the electrical infrastructure of industrial facilities, commercial edifices, and other large establishments. These versatile units combine punching, cutting, and bending capabilities, providing an all-encompassing busbar manufacturing solution. They are indispensable tools for electricians, electrical panel producers, and entities in need of bespoke busbars for their distinct operations.

The operation of a triple-function busbar machine is predicated on material removal and deformation techniques. Initially, raw busbar material is secured within the machine's operational area. The punching mechanism then perforates the busbar, facilitating conductor insertion or component attachment. Subsequently, the cutting mechanism trims the busbar to precise measurements, while the bending mechanism molds the busbar into the required configurations. More sophisticated models may also boast additional functionalities such as notching, cropping, and the processing of round and square bars.

These machines adeptly handle various materials like copper, aluminum, and stainless steel with remarkable precision and efficiency. Available in manual or fully automated variants, the complexity of their automation systems varies. The choice between manual and automated models hinges on the production volume and the requisite precision level.

Varieties of Triple-Function Busbar Machines

A diverse range of triple-function busbar machines caters to the specific demands of different applications, each distinguished by its unique capabilities:

-

Punching Machine: Engineered for creating apertures and notches in busbars, this machine type is frequently employed in construction to fasten electrical fixtures. Models range from straightforward benchtop units to advanced CNC-controlled systems, delivering exceptional accuracy and rapidity.

-

Cutting Machine: Utilized for removing surplus material from busbars and segmenting them into discrete components, cutting machines are crucial for producing busbars with precise lengths and clean edges, which are vital for electrical continuity and structural integrity.

-

Bending Machine: Employed for shaping busbars into diverse forms, such as angles or curves, bending machines ensure busbars fit snugly within electrical panels or casings. Certain models are capable of executing straight-line cutting and bending in a single operation.

Machine selection is influenced by factors such as busbar profile size, material composition (copper or aluminum), desired automation level (from manual to fully automatic), and the necessity for specific finishing operations like grinding or drilling.

Selecting a Triple-Function Busbar Machine

Choosing an appropriate triple-function busbar machine necessitates a thorough evaluation of several criteria:

First, determine the size and design of the busbar you intend to produce, which will dictate the machine type required—stationary machines are optimal for large-scale, consistent production, while portable machines offer adaptability for fluctuating production needs.

Second, contemplate the material you will be processing. The machine must be suitable for the specific material employed in your application, be it copper, aluminum, or another metal.

Third, consider the desired automation level. Fully automatic machines provide high productivity with reduced manual intervention but entail a greater initial outlay. Conversely, semi-automatic machines may offer a more economical alternative if manual labor is available.

Finally, take into account the after-sales service and support from the manufacturer, including the provision of online or video technical assistance to resolve any operational challenges.

By judiciously weighing these factors against your production requirements and budgetary limitations, you can identify the most fitting triple-function busbar machine that aligns with your business goals.

Discovering Triple-Function Busbar Machines on Alibaba.com

Alibaba.com emerges as a premier global marketplace, linking businesses with an extensive array of industrial solutions, including top-tier busbar machines for diverse applications. The platform's vast supplier network spans the globe, simplifying the search for equipment that meets precise production specifications—be it for construction projects or manufacturing operations.

The platform's intuitive interface enables businesses to refine their search based on key parameters such as local service location, core components, machinery test reports, functions, and construction materials. This customization capability ensures that businesses can pinpoint machines that meet their unique needs without compromise.

Furthermore, Alibaba.com underscores its commitment to secure transactions through services like Trade Assurance, which safeguards payments until delivery confirmation. This dedication to reliability and trust positions it as an exemplary source for procuring busbar machines that bolster productivity and foster growth across various industries.

Frequently Asked Questions About Triple-Function Busbar Machines

What is the purpose of a busbar machine?

Busbar machines are instrumental in fabricating copper or aluminum busbars, which are crucial for power distribution systems due to their conductive and durable properties.

How does a CNC busbar machine function?

A CNC busbar machine is governed by computer programming to execute precise cutting, punching, and shaping of conductive strips through an array of tools and methods.

Which materials are compatible with a busbar machine?

Busbar machines can process a variety of materials, including copper, aluminum, stainless steel, and their alloys, provided the machine is tailored for the specific material and its application.

What are the primary considerations when selecting a busbar machine?

Important considerations include the busbar material type, the specifications required (size, shape, and core components), the machine's production capacity, and its user-friendliness.

Is it possible to customize busbar machines to meet specific needs?

Indeed, many Alibaba.com suppliers offer customization options to accommodate specific requirements such as busbar dimensions, shape, material, and functional specifications.

What kind of after-sales services are typically offered with a busbar machine purchase?

After-sales services may encompass online support, video technical assistance, and field maintenance and repair services, with availability varying by supplier.

How can I ensure the correct voltage selection for my busbar machine?

Verify the voltage specifications of the electrical system where the machine will operate (e.g., 380V or 220V) and confirm that it matches your facility's requirements.

Do busbar machines vary across different industries?

Certainly, there are specialized busbar machines designed to meet the unique demands of various sectors such as construction, manufacturing plants, machinery repair shops, and others.

What are the benefits of using a multifunctional busbar machine?

Multifunctional busbar machines provide the benefit of executing multiple operations like cutting, punching, and bending within a single apparatus, enhancing production efficiency.

How does a hydraulic busbar machine differ from a standard one?

A hydraulic busbar machine employs pressurized fluid to exert force, in contrast to standard machines that typically rely on electric motors or mechanical systems. Hydraulic units offer greater power and precision but may incur higher maintenance and operational costs.

Is specialized training necessary to operate a busbar machine?

Although trained professionals should operate busbar machines, many systems feature user-friendly interfaces that necessitate minimal training for secure operation.

Can a busbar machine accommodate both copper and aluminum?

Some busbar machines are engineered to handle both copper and aluminum. When choosing a machine, it is crucial to ensure compatibility with the intended material.