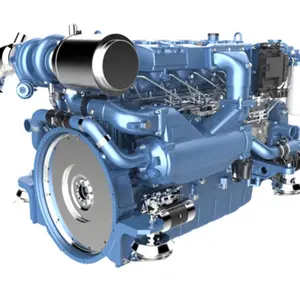

Understanding the 2100 Diesel Engine

The 2100 diesel engine stands as a pivotal component in the realm of industrial machinery, powering a diverse range of equipment from lathes to conveyors. This engine type is renowned for its durability and efficiency in various applications, including agriculture, construction, and manufacturing.

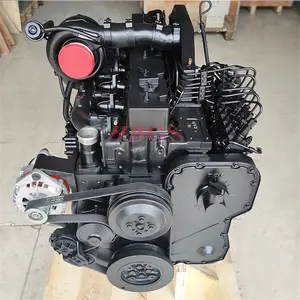

Components and Replacement Parts

When it comes to maintaining the 2100 diesel engine, a comprehensive inventory of parts is essential. Components such as cylinder blocks, gasket heads, and injection pumps are critical for engine reconditioning. For those looking to enhance engine performance, upgrading piston rings and rod bearings can be considered, ensuring the longevity and reliability of machinery.

Applications and Versatility

The versatility of the 2100 diesel engine is evident in its wide range of applications. From powering textile plants to supporting plastic shaping workshops, this engine category is integral to keeping various industrial operations running smoothly. Its adaptability also extends to vehicles and heavy-duty industrial equipment, underlining its importance in the industrial sector.

Features and Materials

The construction of the 2100 diesel engine involves robust materials designed to withstand rigorous industrial demands. The use of durable metals in cylinders and bearings contributes to the engine's resilience and performance under high-stress conditions. This focus on material quality ensures that each engine component delivers optimal functionality.

Advantages of Reconditioning

Opting for engine reconditioning with parts like screws, ball bearings, and cylinders can significantly extend the life of machinery. This approach not only enhances the performance of existing engines but also serves as a cost-effective alternative to purchasing new engines, providing a practical solution for businesses looking to optimize their operations.

Alternative Solutions

In instances where the 2100 diesel engine may not suffice, exploring alternative engine options is a viable route. The platform offers a selection of diesel and electric engines suitable for a variety of industrial needs, from forklifts to mining drills. This ensures that businesses can find the right engine solution to meet their specific requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4