Exploring the Versatility of Smelting Plants

A smelting plant is an industrial location where the process of extracting metals from their ores, known as smelting, takes place. This complex procedure involves heating and melting materials to separate the desired metal. The applications of smelting plants are diverse, ranging from iron smelting plants to aluminum smelter plants, each designed to handle specific metals and their unique melting points and properties.

Types and Applications of Smelting Plants

The variety of smelting plants includes copper smelting plants, zinc smelters, and lead smelting plants. Each type caters to different industrial needs, such as creating steel from iron or refining copper. The choice of plant depends on the metal being processed and the scale of operation, with some plants specializing in bulk metals like iron and aluminum, while others focus on precious metals like gold and silver.

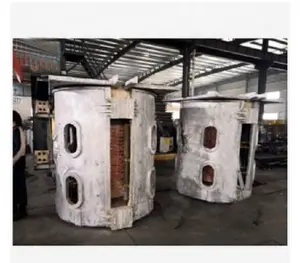

Features and Technical Specifications

Smelting plants are equipped with advanced features to ensure efficient operation. These include large capacitor banks for current stabilization and safety systems with circuit breakers to prevent faults. The melting process can be conducted in open or enclosed furnaces, with some plants requiring dual pots for melting and transportation. Operational temperatures in these plants can reach between 1,750 to 2,100 degrees Celsius, with melting speeds varying based on the metal and equipment used.

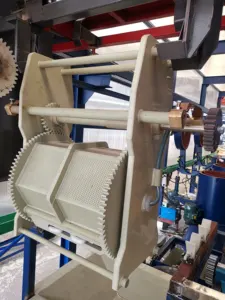

Design and Material Considerations

The design of a smelting plant is critical for its function, with some capable of handling up to 20 tons of material. The construction materials must withstand extreme temperatures and conditions, ensuring longevity and safety. Additionally, melting pots in these plants can tilt up to 95 degrees for efficient metal pouring, and water-cooling systems are in place to manage the high temperatures generated during the smelting process.

Advantages of Modern Smelting Technology

Modern smelting plants leverage electrical induction systems for heating and hydraulic pressure systems for tilting furnace pots. The integration of PLC systems for operation streamlines the smelting process, enhancing precision and control. These technological advancements contribute to the efficiency and reliability of metal production in plants such as steel smelting plants and metal smelting factories.

Choosing the Right Smelting Plant

Selecting the appropriate smelting plant is crucial for any metal processing endeavor. Factors such as the type of metal, required temperature range, and plant capacity play a significant role in the decision-making process. With a comprehensive range of options available, from iron ore smelting plants to zinc smelting plants, Alibaba.com serves as a platform where businesses can connect with suppliers to find the plant that meets their specific needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4