Hanger Making Machine: An Overview

The hanger making machine stands as a cornerstone in the manufacturing sector, catering to the production of a variety of hangers used in homes and businesses alike. This machinery is engineered to transform raw materials into fully functional hangers through a series of mechanical processes. The versatility of these machines allows for the production of different types of hangers, including those for clothes, suits, and skirts, ensuring that they meet the diverse needs of the market.

Types of Hanger Making Machines

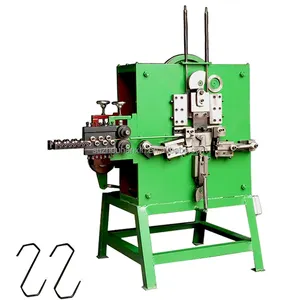

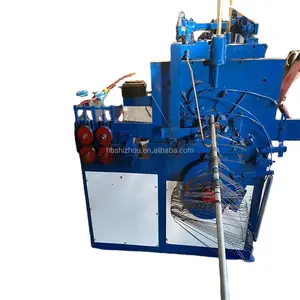

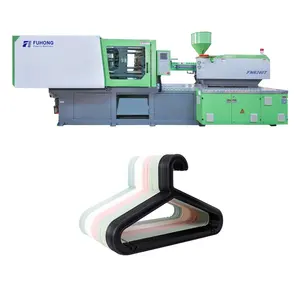

There are several types of hanger making machines, each designed to handle specific materials and production requirements. The wire hanger making machine is adept at shaping metal wires into sturdy hangers, commonly used for a variety of garments. In contrast, the plastic hanger making machine is specialized for the production of plastic hangers, which are ubiquitous in retail and personal wardrobes due to their lightweight and cost-effectiveness. For a more eco-friendly option, the wooden hanger making machine fabricates hangers from wood, catering to a niche market that values sustainability and aesthetic appeal.

Applications and Features

The application of hanger making machines extends across the textile and retail industries, where the demand for efficient and reliable hangers is ever-present. These machines are equipped with advanced features that enhance production efficiency, such as automated feeding systems and precision molds. The hanger hook making machine, for instance, is integral in forming the hook, a critical component of the hanger that ensures a secure grip on hanging rods. The incorporation of innovative technologies in these machines allows for improved accuracy in the final product, which is essential for maintaining consistency in mass production.

Materials and Advantages

Hanger making machines are capable of processing a range of materials, from metal and plastic to wood. The choice of material impacts the machine's configuration and the end product's characteristics. For instance, machines designed for cloth hanger making often prioritize speed and volume, as these hangers are in high demand in both commercial and residential sectors. The advantages of utilizing these machines include increased production speed, reduced labor costs, and the ability to recycle materials, which is particularly beneficial for businesses focusing on sustainability.

Choosing the Right Machine

Selecting the appropriate hanger manufacturing machine is crucial for businesses to ensure that they can meet their production goals and maintain quality standards. Factors to consider include the type of hanger to be produced, the material being used, and the desired production capacity. While the hanger making machine price is a consideration, it is essential to focus on the machine's features, durability, and compatibility with existing production lines to ensure a wise investment.

Conclusion

In conclusion, the hanger making machine is an indispensable asset for manufacturers in the garment and storage industries. With the ability to produce a variety of hanger types, these machines offer flexibility and efficiency to businesses looking to scale their operations. By carefully selecting the right machine based on material, type, and production needs, manufacturers can significantly enhance their production capabilities and meet the ever-growing demand for hangers in the global market.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4