Gypsum Ceiling Board Making Machine: An Overview

The gypsum ceiling board making machine stands as a cornerstone in the production of gypsum-based ceiling solutions. This machinery is designed to streamline the manufacturing process of ceiling boards, which are widely used in construction due to their aesthetic appeal and functional properties such as sound insulation and fire resistance.

Types and Applications

Diverse in its capabilities, the machinery caters to various types of gypsum boards. From the standard gypsum tile making machine to advanced systems for decorative tiles, these machines serve a broad spectrum of applications. They are pivotal in producing tiles for residential, commercial, and industrial ceilings, each machine tailored to meet specific dimensional and design requirements.

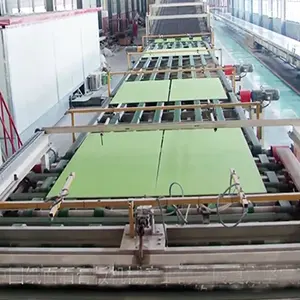

Technical Features

A gypsum board manufacturing machine is equipped with features that ensure efficiency and precision. The technology behind these machines includes automated batching systems, drying sections, and cutting-edge forming stations. This ensures a consistent quality of the ceiling boards, with precise dimensions and a smooth finish, ready for installation.

Materials and Advantages

The machines utilize a blend of gypsum, paper facing, and additives, creating boards that are lightweight yet durable. The advantages of using a gypsum board production line include the ability to produce various sizes and thicknesses, catering to custom specifications while maintaining material integrity and performance.

Operational Excellence

Operational efficiency is at the heart of the gypsum board making machine. With an emphasis on low maintenance and energy consumption, these machines are designed to be cost-effective in the long run. They are also adaptable, capable of integrating into existing production lines or serving as standalone units.

Environmental Considerations

Sustainability is a key factor in the design of a gypsum ceiling tile making machine. The production process is geared towards minimizing waste and energy use, contributing to greener building practices. Additionally, the end product is recyclable, which further underscores the environmental benefits of using gypsum ceiling boards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4